Houston Ship Channel Terminal

Retrofit hybrid CP systems installed on 5 docks on the Houston Ship Channel

Project overview:

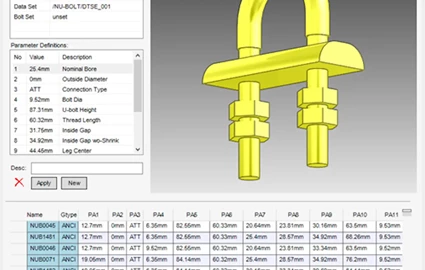

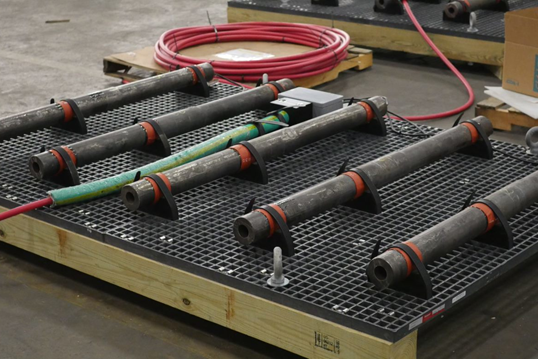

Deepwater Corrosion Services was contracted to design and install a hybrid cathodic protection (CP) system for the Enterprise Houston Ship Channel (EHSC) facility located on the Houston ship channel. A total five (5) docks were selected for life extension designated: Dock B, Dock 1, Dock 4/5, Dock 6/7 and Dock 8/9 (Figure 1). The final design applied a hybrid approach of using impressed current cathodic protection (ICCP) systems for the large clusters of piles and sacrificial anodes (SACP) systems for the individual dolphins. In total, 45 RetroLinks and 15 ICCP anode sleds were sufficient to protect the entire facility. The subsea equipment was installed using divers from US Underwater Services (USUS) and the topside cabling was installed by Doskocil.

Installation specifications:

- Dock B: A total of 13 RetroLinks sacrificial anodes and 14 continuity grounding brackets were installed by USUS on B Dock in 2018. In January 2019, Enterprise had moved forward with demolition and removal of B Dock.

- Dock 1: A total of 32 continuity brackets, 7 RetroLinks, 3 ICCP anodes and 1 transformer rectifier were installed on Dock 1.

- Dock 4/5: A total of 32 continuity brackets, 8 RetroLinks, 6 ICCP anodes, and 2 transformer rectifiers were installed on Dock 4/5.

- Dock 6/7: A total of 16 continuity brackets, 12 RetroLinks, 4 ICCP anodes and 2 transformer rectifiers were installed on Dock 6/7.

- Dock 6/7 Bulkheads: A total of 3 ICCP anode sleds and 1 transformer rectifier were installed on Dock 6/7 bulkhead and all the sheet piles were welded together to make them continuous.

- Dock 8/9: A total of 37 continuity brackets, 7 RetroLinks, 6 ICCP anodes and 2 transformer rectifiers were installed on Dock 8/9.