Tabu, Guntong, Semangkok

Replacement of depleted anodes during pipeline survey campaign in Malaysia

RetroSled™ anode sleds installed on three unprotected pipelines

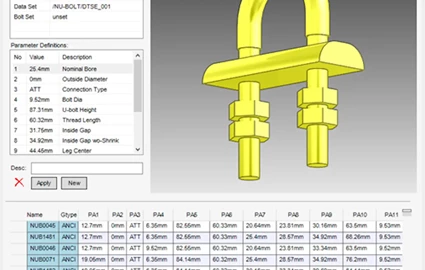

In March, during an ROV survey of three pipelines, EMEPMI discovered that the pipelines’ sacrificial bracelet anodes were depleted and in need of replacement. Spot-replacement of bracelet anodes is prohibitively costly due to lofty vessel day rates. EMEPMI engaged Deepwater Corrosion and our agent, Wasco, to design and supply a semi-remote sled-based retrofit for the three subsea pipelines for a life extension of 25 years (to 2041). Our engineers determined the correct number of RetroSleds™ and RetroClamps™ needed for full protection. The Retrosleds™ were fabricated locally in Malaysia and the RetroClamps™ were shipped from Houston.

The installation was performed from the vessel Atlantis Dweller using an ROV in 60 meters of water on 3 pipelines off the coast of Malaysia. The clamps and sleds were installed by ROV without removing the concrete weight coat on the pipeline. This was a first in the region. The 3 pipelines: The TABU-A to TABU-B Pipeline, the GUNTONG-A to GUNTONG-B Pipeline, and the SEMANGKOK-A to SEMANGKOK-B pipeline

Using the proprietary pipeline attenuation models, Deepwater engineers were able to complete the design quickly. Materials were manufactured and delivered to the dock within one month. The estimated installation time included in the client’s budget was 10 days. The vessel, with ample lifting capacity for our minimalist, rigid anode sleds, was able to install the RetroSleds via RetroClamps at 6 locations on 3 pipelines in 4 days.

CP readings were taken on each platform at each end of the pipelines, before and after the anode sled installation. Post-install readings were between -0.999 V and -1.014 V vs Ag AgCl, indicating that the sleds adequately shifted potentials, polarizing and protecting the assets.

Results

CP readings were taken on each platform at each end of the pipelines, before and after the anode sled installation. Post-install readings were between -0.999 V and -1.014 V vs Ag AgCl, indicating that the sleds adequately shifted potentials, polarizing and protecting the assets.

Related content

RetroSled anode sleds installed on three unprotected pipelines.

In March, during an ROV survey of three pipelines, EMEPMI discovered that the pipelines’ sacrificial bracelet anodes were depleted and in need of replacement. Spot-replacement of bracelet anodes is prohibitively costly due to lofty vessel day rates. EMEPMI engaged Deepwater Corrosion and our agent, Wasco, to design and supply a semi-remote sled-based retrofit for the three subsea pipelines for a life extension of 25 years (to 2041). Our engineers determined the correct number of RetroSleds and RetroClamps needed for full protection. The Retrosleds were fabricated locally in Malaysia and the RetroClamps were shipped from Houston.

The Installation was performed from the vessel Atlantis Dweller using an ROV in 60 meters of water on 3 pipelines off the coast of Malaysia. The clamps and sleds were installed by ROV without removing the concrete weight coat on the pipeline. This was a first in the region. The 3 pipelines: the TABU-A to TABU-B Pipeline, the GUNTONG-A to GUNTONG-B Pipeline, and the SEMANGKOK-A to SEMANGKOK-B pipeline

Using the proprietary pipeline attenuation models, Deepwater engineers were able to complete the design quickly. Materials were manufactured and delivered to the dock within one month. The estimated installation time included in the client’s budget was 10 days. The vessel, with ample lifting capacity for our minimalist, rigid anode sleds, was able to install the RetroSleds via RetroClamps at 6 locations on 3 pipelines in 4 days.

CP readings were taken on each platform at each end of the pipelines, before and after the anode sled installation. Post install readings were between -0.999 V and -1.014 V vs Ag AgCl, indicating that the sleds adequately shifted potentials, polarizing and protecting the assets.