Cathodic protection

The science of subsea corrosion control

What is cathodic protection?

Cathodic Protection 101

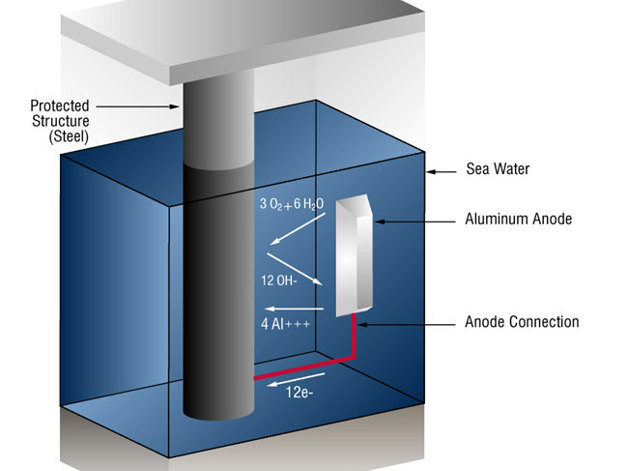

Cathodic protection prevents corrosion by converting all of the anodic (active) sites on the metal surface to cathodic (passive) sites by supplying electrical current (or free electrons) from an alternate source. Usually this takes the form of galvanic anodes, which are more active than steel.

Cathodic protection services

CP inspection

Measuring the cathodic protection potentials on a structure or pipeline using reference electrodes gives engineers the data they need to evaluate anode performance.

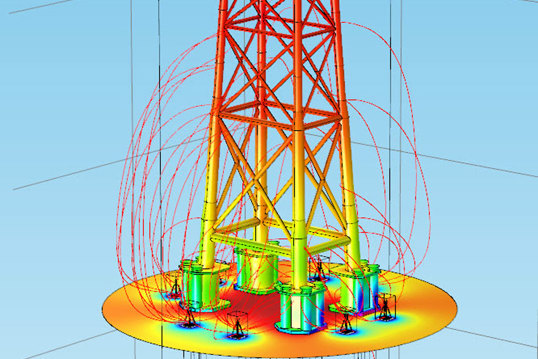

CP design

Surface area, coatings, electrolyte properties and design life determine the amount of cathodic protection required. Designing for anode retrofits on existing structures must also consider the state of the original anode system.

CP manufacturing

Building sacrificial and impressed current anode systems that perform for up to 25 years offshore requires high-quality anode materials and rugged construction.

Cathodic protection projects

Floating production

Anode retrofit projects for FPSO hulls and floating production.