I-Rod® pipe supports

Prevent crevice corrosion at pipe supports

I-Rod® product family

NU-BOLT® ASSEMBLY

The Nu-Bolt® assembly consists of a U-bolt with Polyshrink™, four nuts and a cut-and-drilled piece of half-round I-Rod® material. Available in sizes up to 42".

I-ROD®

I-Rod® material is sold in half-round lengths or cut and drilled for U-bolts.

Video: How I-Rod® works

I-Rod® eliminates corrosion at pipe supports

The problem:

Corrosion at pipe supports is a common problem that results in serious damage to pipes. A round pipe on a flat surface traps water along the contact area, quickly causing the paint to fail and pipe corrosion to begin.

The solution:

I-Rod® prevents corrosion by eliminating moisture trapped beneath the pipe. I-Rod’s half-round shape minimizes the pipe’s contact area and allows water to evaporate before corrosion occurs.

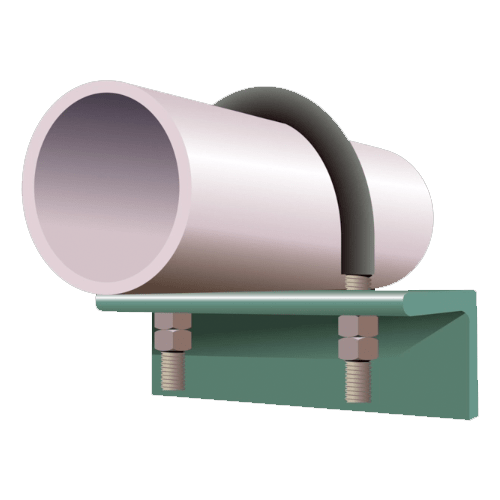

A FLAT SURFACE

A pipe on a flat surface exposed to the elements is not properly protected against corrosion because there’s no room for air to flow beneath it.

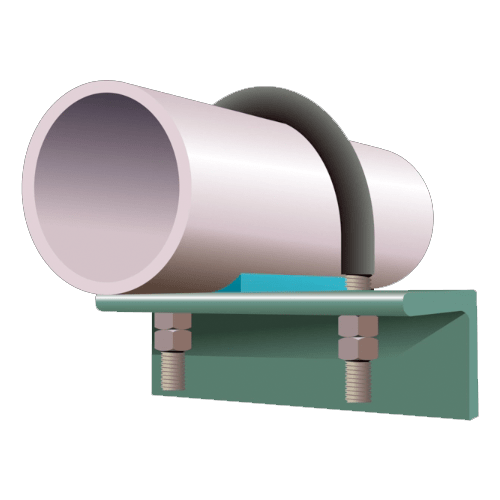

WATER IS TRAPPED

The space between the pipe and support forms a crevice that traps water, causing corrosion resulting in rapid wall loss.

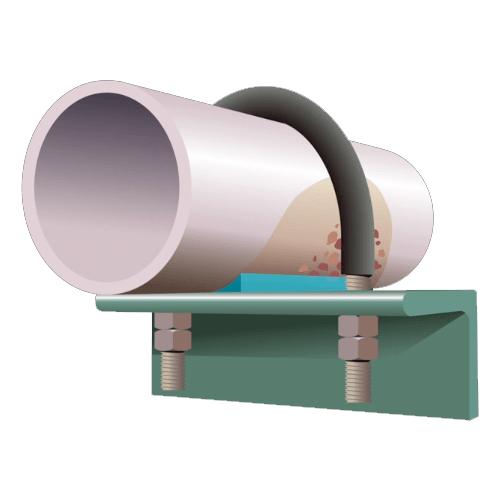

CORROSION BEGINS

The pattern of crevice corrosion is very recognizable as it spreads from the point of initial paint failure.

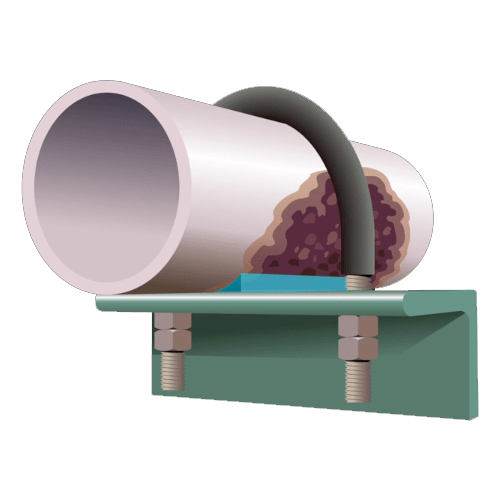

WALL LOSS ON PIPE

The problem worsens as the crevice grows and water can’t escape. Corrosion accelerates wall loss that can cause dangerous leaks.

How do I-Rod® supports work?

1. The proprietary hydrophobic material has high compressive strength and will not crack, creep or cold-flow.

2. The pipe is supported by I-Rod’s half-round shape to minimize the contact area and ensure that water evaporates before damaging the paint.

3. I-Rod® electrically isolates the pipe from metal supports, preventing galvanic corrosion between dissimilar metals.

4. Nu-Bolts™ are covered in PolyShrink™ to protect the paint on the pipe during installation.

Video: I-Rod® in-depth

How to order I-Rod® material, Nu-Bolt™ and more

I-Rod® pipe supports are only available from Deepwater Corrosion Services and our licensed distributors and international resellers. Please send us an email for a list of local distributors.

Beware of I-Rod® imitations, which are prone to early failure

I-Rod® material is extremely durable and can support enormous amounts of weight. While conducting offshore inspections, our technicians routinely discover imitations of I-Rod® that have broken or crushed, leaving pipes dangerously unprotected. Usually, these are low-grade imitations, but some use high-quality materials (Delrin and Teflon for example) with material properties unsuited for this application.

The dangers of FRP wear pads

Loose FRP pads catch and trap water against the pipe, causing significant corrosion in a short amount of time. Since pads make inspection impossible, the problem is not apparent until the pipe fails – which can be catastrophic. Sealing the seams to prevent water intrusion is rarely effective because the pipe and pad expand at different rates. Adding insult to injury, FRP pads cost at least $1,000 each to install.

A cautionary tale about FRP wear pads

A number of years ago, we learned of a facility that decided – rather inexplicably – to replace most of their existing, undamaged I-Rod® with FRP wear pads. The new FRP pads failed in less than a year, causing damage that cost $700 per location to repair. Undeterred, the operator replaced them with new FRP pads at a cost of $1,000 per location, and again, the pads failed within a year. After the damage was once again repaired at a cost of $700 per location, the FRP pads were all replaced with I-Rod®. The brief flirtation with FRP pads ultimately caused hundreds of thousands of dollars in damage. At the facility’s locations where I-Rod® had remained in service, there was no damage at all. The operator subsequently re-wrote their global spec to include I-Rod® on all pipe supports.

Additional information about I-Rod®

Frequently asked I-Rod® questions

Here are answers to some of your I-Rod® questions, and maybe a few you might not have thought to ask:

Crevice corrosion caused explosion

Corrosion hidden beneath a wear pad on a 10-inch pipe caused a massive refinery explosion. Here’s the story:

I-Rod® installation 13 years later

After 13 years, we inspected the first offshore structure where I-Rod® was specified. See what we found:

I-Rod® installation 28 years later

We revisited the same platform 15 years later and compare photos (like both of these) from then and now:

Custom sizes available

I-Rod® products are available in custom sizes for any applications specifying dimensions not found in our standard product listings. You're not limited to choosing from our existing sizes; just give us the required dimensions you need.

We can supply Nu-Bolts™ with custom U-bolt heights, longer thread lengths, larger or smaller inside gaps, longer or shorter flats, countersunk holes or any other non-standard configurations you might require.

Depending on the cradles they need to fit, I-Rod® Clips can be made longer, shorter or with a smaller inside radius to fit smaller clamps.

We can also install our polyshrink on other manufacturers’ U-bolts if desired.

Just give us the numbers if you don’t see exactly what you need listed in our catalog or on I-Rod.com and we’ll be happy to accommodate you.