RetroBuoy™

The most efficient and environmentally responsible cathodic protection retrofit system available

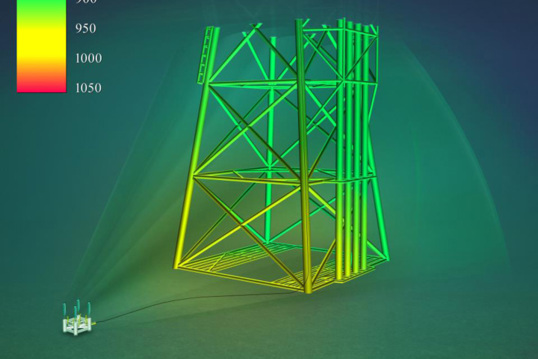

RetroBuoy™ is a high-capacity impressed-current cathodic protection system, designed primarily as a retrofit for existing structures. It utilizes impressed-current titanium-anode rods housed in buoyant floats. This configuration keeps the anodes in constant contact with seawater, maximizing the efficiency of the cathodic protection.

Very cost efficient

RetroBuoy™ provides the lowest installed cost per ampere/year of any CP system available.

To maintain appropriate levels of protection, individual RetroBuoy™ anode sleds can be rated anywhere from 150 to 500 amps.

The compact size and remote location of the RetroBuoy™ on the seabed simplifies the installation procedure and increases the cost-effectiveness of the retrofit.

These installation costs typically dominate a large offshore cathodic protection upgrade and the RetroBuoy™ eliminates most superfluous work.

Video: Shell Leman ICCP Retrofit

Key design factors

Superior efficiency

Mixed-metal-oxide-activated titanium electrodes allow the anode sled to be operated at a very high current output. Installing the electrode elements in buoyant modules ensures that they remain surrounded by clean seawater.

Compact protection

The RetroBuoy's sled base is compact and easily handled by most offshore installation vessels.

Customizable cabling

Routing the ICCP system cable can be done in a variety of ways depending on project needs. Our partnerships with key transformer / rectifier manufacturers in the US and UK allow us to provide complete systems in compliance with any local electrical requirements and safety codes.

Durable design

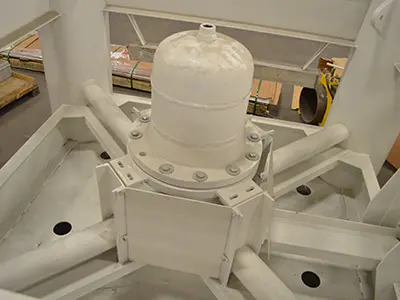

The oil-filled, pressure-compensated electrical junction box that houses the electrode cables allows the system to operate efficiently at any depth.

Video: RetroBuoy™ installation

RetroBuoy™ overview

Current output

Each RetroBuoy™ can put out up to 500 amps of cathodic protection current, enough to protect 80,000 sq. ft of steel.

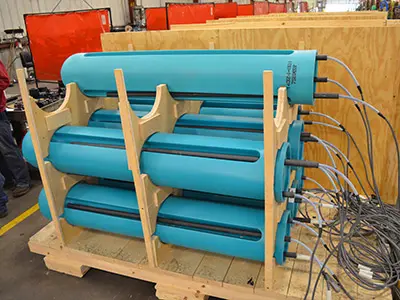

Anode floats

Each anode float contains three mixed-metal oxide anodes.

Transformer rectifier

Each RetroBuoy™ is powered by a TR on the surface.

Cable

Depending on the particular installation, different cable specs are used. All cables are double-armored single conductors. Cable management through the splash zone is a critical aspect of platform retrofits. J-tubes or I-tubes can be used. Dynamic cable can be configured in a lazy S for FPSO installations.

Specifications

| Model name | Anodes modules | Current rating (A) | Anode to structure* | Anode to sea floor | Applications |

|---|---|---|---|---|---|

| RetroBuoy Junior | 1 | 150/200 | 3m(10ft) | 0.7m (2.3ft) | Docks and harbors, small offshore structures, jacket complexes, in tropical oceanic conditions |

| Retrobuoy (RB-4) | 4 | 400/500 | 30m(100ft) | 2.1m (7ft) | Large offshore structures in harsh oceanic conditions with an unstable sea floor |