Arklow Bank

Deepwater installs ICCP anode system to protect wind farms in the Irish Sea

Seven offshore wind turbines had prematurely failing cathodic protection anodes. Deepwater developed a completely new type of impressed-current anode system.

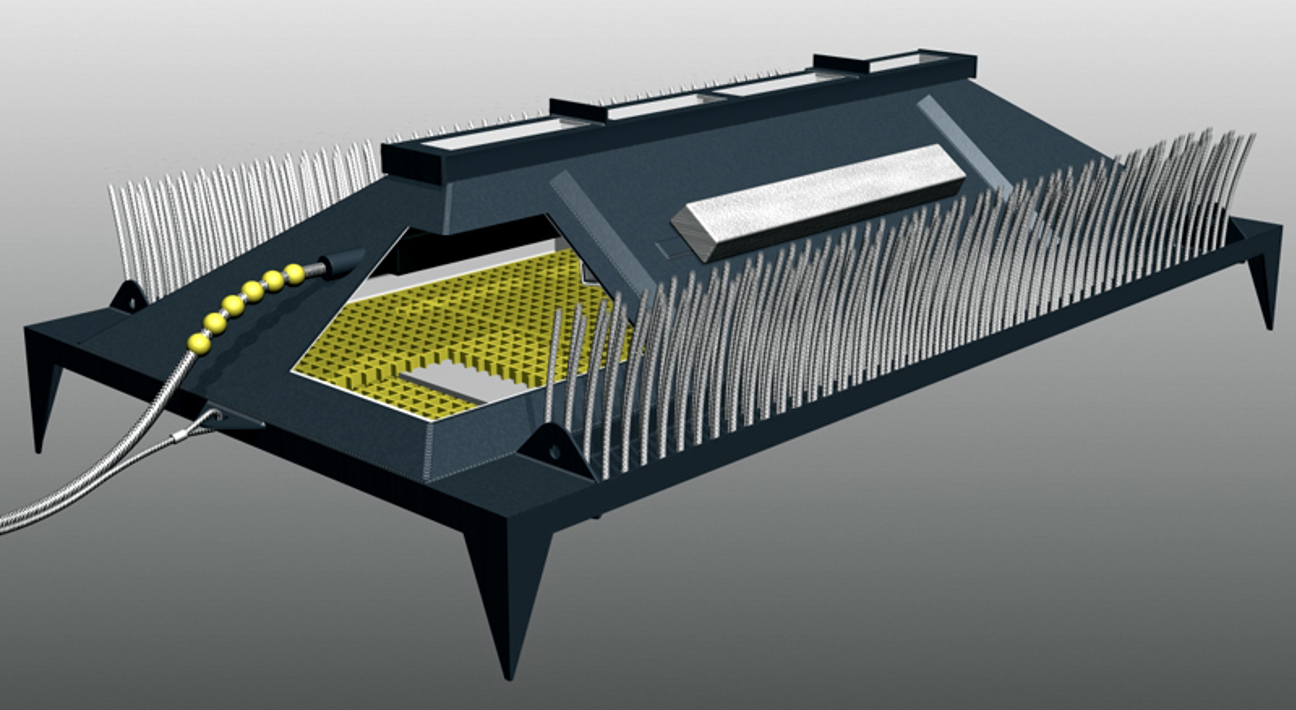

Deepwater was commissioned by the operator of the Arklow Field to develop an anode retrofit system for the seven monopiles there with low cathodic protection readings. The system had to function in the 8 m -10 m water depth and had to utilize the power from the turbine to run. As there was no existing technology to fit the requirements, Deepwater developed the VSE™ anode system to scour and self-bury, creating a seawater envelope beneath the sea floor. Within the envelope, an MMO anode is kept free from mud contamination, allowing it to output the maximum cathodic protection current regardless of the tide above. The VSE™ was also designed with a low profile to minimize the risk of snagging by fishing activities while the system silts over.

All together, the retrofit cathodic protection (CP) system consisted of:

• 7 x Vaulted Seawater Envelope anode systems (aka VSE)

• 7 x Transformer rectifiers

• 7 x DR-2 CD monitors (part of the monitoring system)

Seven monopiles in eleven days

The VSE™ assemblies were installed 10 m to 15 m from the base of the monopiles. Dual-armored single-conductor cable was routed from the VSEs™, across the bottom to the base of the monopiles and then up through specially-installed I-tubes to the rectifiers located at the (+) 13 m elevation. The systems, including I-tubes, were installed on all seven monopiles in a total of eleven work days utilizing a dive support boat with lifting “A” frame. In addition, DR-2 CD™ polarization monitors were installed to monitor the performance of the new CP system.