Technical Paper

Corrosion at pipe supports: Causes and solutions

by James N. Britton (2002)

Abstract

Corrosion at pipe supports is one of the leading causes of topside process piping failure. This paper will discuss the various corrosion mechanisms that occur at pipe supports if they are not adequately protected. I-Rod, a proven method of prevention with a long record of successful application will be presented. This paper also discusses inspection strategies for pipe supports and provides a simplified visual screening method that has proved useful in mechanical integrity programs.

Introduction

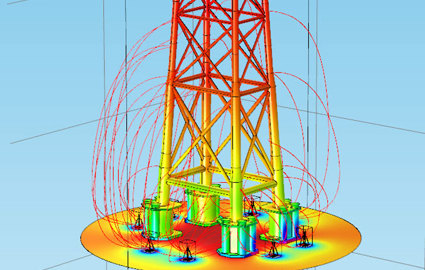

The writer's company is engaged in the inspection of offshore oil and gas facilities in the Gulf of Mexico as well as other international production areas. A major part of those inspections is the integrity of topside process systems, piping, and associated vessels and tanks. There is no doubt that statistically, corrosion at pipe supports is the most common cause of external piping corrosion failure. It is for this reason that the writer's company developed the solution most widely employed in the Gulf of Mexico to eliminate this problem (I-Rod® brand pipe supports).

Types of pipe supports

1. Standard beam support:

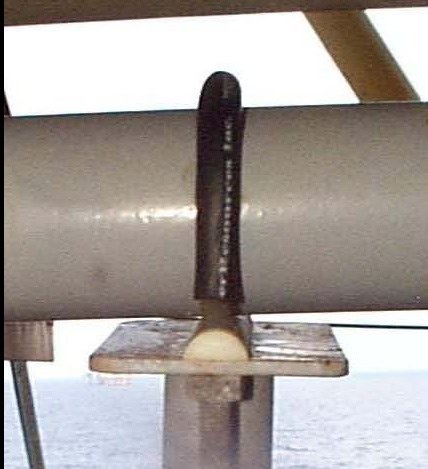

The pipe is rested on, or secured to, a support member usually of a standard structural shape (I-beam, wide flange beam, angle, channel, etc.). The pipe may be secured to this member with a stabilizing U-bolt (Figures 1 and 2 below).

Figure 1 - Typical I-beam pipe support (note that the pipe is in full contact with the I-beam)

Figure 2 - U-Bolt stabilized beam supports

2. Saddle clamp:

Pipe is clamped between two rolled plates. One of these plates has a structural element welded to it which attaches the pipe to the support structure (Figures 3 & 4 below).

Figure 3 - Typical half-saddle clamp

Figure 4 - Full-saddle clamp

3. Welded support

This type of support involves welding a part to the pipe which is usually free to move at the interface to the support. There are a number of variations on this theme, and is a common approach for insulated piping systems. (Figure 5 below).

Figure 5 - Typical welded pipe support. Allows for movement at support interface, but allows corrosion as well.

4. Others

There are a number of other methods used, such as flange bolt supports, various type of pipe hangers and other specialty-type supports. However, the first two categories account statistically for better than 95% of support points on a typical offshore structure.

Problems

Not surprisingly, it is the beam supports and the saddle clamps that have historically caused the majority of the problems. They have the following undesirable features in common:

1. Crevice forming - This is the root of the problem: the formation of a crevice at the pipe surface.

2. Water trapping - These support types all allow water to be trapped and held in contact with the pipe surface.

3. Poor inspectability and maintainability - These support types make it virtually impossible to paint or otherwise maintain some areas of the pipe at the support. Visual inspection is often difficult, and until fairly recently, it was also very difficult to inspect these areas with NDT methods.

4. Galvanic couple forming - Some of these support types may develop bi-metallic contact. Even though both the pipe and support are steel, the metallurgical differences can still provide a small potential difference to create a corrosion cell.

The corrosion mechanism

It is a common misconception that metal-to-metal contact coupled with water entrapment is the major cause of corrosion at these points. This is not the case; the sequence of events is as follows:

1. Water is trapped - The very nature of the supports allows water to be held in contact with the painted pipe surface as well as the paint on the support element.

2. The paint system fails - Even if the paint on the pipe and support beam are perfect, the paint system is designed for atmospheric exposure and not immersion service. The longer the paint surface is continuously exposed to water, the more it softens. As the pipe softens, it is inevitable that the steel substrate will be directly exposed to the water.

3. Corrosion is initiated - The small area of steel now exposed to oxygenated water (often with high chlorides) starts to corrode.

4. Corrosion undercuts paint film - The initial corrosion soon undercuts and spreads (Fig. 6 below). Soon the whole support area is bare steel.

5. Crevice corrosion starts - From this point on, the crevice corrosion driven by differential aeration takes over from the general corrosion mechanism that initiated the corrosion. As corrosion products build, they further restrict oxygen diffusion and the oxygen concentration gradient gets steeper. Pitting now becomes the main problem with corrosion rates accelerating by an order of magnitude. (Fig. 7 below)

6. Pipe fails - If the inspection program is not set up to detect this mostly concealed wall loss, the pipe will fail.

Figure 6 - Paint is progressively undercut away from initiation site

Figure 7 - Advanced crevice corrosion

Historical solutions

The industry has long been aware of the problem but has failed to appreciate the true causes; this is evidenced by some of the following solutions that have been implemented to stop the problem which have actually accelerated the problem.

Rubber pads and liners

As previously stated, it was thought that the metal-to-metal contact was the main problem causing pipe support corrosion. As a result, initial designs incorrectly targeted this aspect of the supports. Some operators still use rubber pads of varying types in an attempt to solve this problem, despite industry knowledge that they are counter-productive. (Fig. 8 below) In fact, rubber pads under pipes do a wonderful job of reducing the life of the pipe. The crevice that was formed without the rubber pad is mild in comparison to the new crevice, which now has the ability to suck water in (by capillary action). Not only does the pad invite water in, it is better at holding it trapped against the pipe surface since air circulation and natural evaporation is eliminated. The situation is further worsened by the length of the crevice which allows an oxygen concentration gradient to go from full natural concentration to anaerobic in a few centimeters.

Figure 8 - Rubber pads accelerate crevice corrosion

Fiberglass pads

Contoured pads attached to the pipe at support points (Fig. 9 below). Obviously, another attempt to eliminate metal-to-metal contact. This is better than the rubber pads, but still allows a crevice to be formed at the pipe's surface.

Figure 9 - Fiberglass contoured pads still risk crevice corrosion failure

Welded supports

The welded support is a viable solution. However, it adds significant cost to a typical project both in terms of construction and inspection. In some situations, it would be undesirable to make so many external longitudinal welds to a pressured piping system. There have been some other solutions adopted, none of which really addresses the major cause of the problem: Water entrapment.

The optimal solution

Clearly, the solution must address the root causes of the problem and should have certain features that make application practical. The important features of one successful solution that is in widespread use throughout the offshore community are as follows:

1. The crevices at the pipe surface and the ability to trap and hold water in contact with the pipe surface must be eliminated.

2. As a secondary concern, metal-to-metal contact should be eliminated if possible.

3. The solution should allow easy maintenance and inspection of the pipe at the support point.

4. The system must provide complete support to the piping system.

5. The system will ideally be non-size-specific.

6. It must be applicable to new construction and retrofits, and should require no hot work to install.

7. It must be cost-effective.

The half round, high-strength thermoplastic I-Rod® (Fig. 10 below), meets all of the above requirements. The half-round configuration minimizes the crevice at the pipe and allows no water accumulation. The standoff provided allows easy inspection and maintenance at the support. The metal-to-metal contact is eliminated, and if used with an insulated bolt (Fig. 11 below), the pipe can be totally isolated from the support structure. The low-cost material has been selected and configured to optimize compressive strength while exhibiting very low creep. The material can be deployed as a continuous dressing to the top of a pipe-support beam (Fig. 12 below), or can be integrated with a stabilizing U-bolt (Fig. 13 below). Either way allows cold work installation for new construction or retrofit applications.

When using U-bolts, it is important to apply a polyolefin sleeve over the shank of the bolt. This reduces the risk of cracking the paint film around the pipe as the bolt is torqued down.This material provides the right combination of hardness and durability to protect the pipe paint but avoids setting up a capillary crevice around the circumference of the pipe.

Figure 10: The half-round pipe-support interface (trademarked as I-Rod®)

Figure 11 - Rod installed with polyolefin-sheathed U-bolt

Figure 12 - Rod installed as beam dressing

Figure 13 - Typical rod and U-bolt stand-alone support

Proven performance

The I-Rod® system described above was first introduced in the mid 1980s; now there are thousands of offshore structures worldwide using this system. The first platform to be completely fitted with the material was installed in the Gulf of Mexico in 1989. A more recent re-inspection in 2002 revealed no corrosion at any pipe-support points, and no degradation of the material. These pictures show the pipe support condition after 13 years offshore (Fig. 14 - 16 below).

Figure 14 - Beam dressing supports after 13 years offshore

Figure 15 - Rod in place under pig-launch barrel after 13 years

Figure 16 - More rod and bolt combinations after 13 years offshore

Added benefit

A side benefit to the application of this system was discovered by a major Gulf Coast fabricator. When using the material, which was attached to the upper surface of pipe racks with a special double-sided adhesive tape, it was discovered that the pipe fitting and installation was accomplished with virtually no installation damage to the paint system on the piping. This was particularly valuable in reducing the number of spot repairs that had to be made before delivery of the deck structures.

Material selection

As one would expect with such an apparently simple solution, there have been many attempts to copy it. This usually results in an unsatisfactory result, as most of these materials do not possess the required properties. The materials will usually crush under the load (Fig. 17 below) or will creep with time causing the support to loosen (Fig. 18 below). In either case, the crevice control and desirable properties are lost.

Figure 17 - Imitations made of low-grade material are crushed under load

Figure 18 - Some "look-alike" materials creep with time

Inspection of pipe supports

While cataloging the extent and severity of the problem, it was necessary to develop inspection strategies that would allow high-risk items to be addressed before failure. In recent years, improvements in guided-wave ultrasonic inspection have allowed a more quantitative approach to this type of inspection, but this is a costly and relatively time-consuming process. It was necessary to have a visual guideline that would help to screen the supports that required further inspection. While deceptively simple, the system has worked very well, and – when combined with other risk-based drivers that affect likelihood and consequence of failure – should allow rapid screening of large numbers of support points:

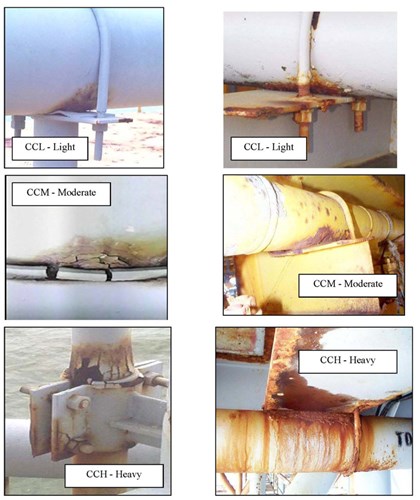

The corrosion that we are looking for is crevice corrosion, as opposed to general corrosion. This corrosion is then graded in three levels: light moderate and heavy. Definitions used to define these are as follows:

CC-L (Light Crevice Corrosion) - Corrosion products visible but no evidence of layered scaling.

CC-M (Moderate Crevice Corrosion) - A single layer of corrosion scale is visible at the edge of the crevice.

CC-H (Heavy Crevice Corrosion) - Copious corrosion product leaching and visible multi-layer corrosion scale is visible.

When investigated more closely, the CC-H situations normally show a wall loss at the deepest pit of >40%. A visual guide is provided for inspectors to assist in making the correct call (Fig. 19 below).

Figure 19 - Comparison of crevice corrosion severity at pipe supports

Summary and conclusions

When designing pipe supports, avoid the use of saddle clamps wherever possible. Never use a rubber pad between a pipe and a pipe support if the area is exposed to a corrosive environment. When using U-bolts to stabilize piping, always use polyolefin-sheathed bolts. The half-round rod solution has proven to be very effective in controlling pipe-support corrosion over the last 15 years on thousands of offshore structures.

No reports of pipe support failures or even repairs have been received from structures fitted with the I-Rod® system.

For more information about I-Rod® brand pipe supports, visit http://stoprust.com/i-rod-pipe-supports/

Want to receive an email when Deepwater publishes new corrosion-related technical papers, case studies, and more? Sign up for our Corrosion Newsletter using the form below. You can unsubscribe at any time.