Tank weld-on anode replacement

Cathodic protection for a large tank at a chemical plant

Weld-on anodes, monitoring panel installed on tank at chemical plant

Deepwater Corrosion Services provided local cathodic protection (CP) using 12 weld-on zinc based anodes for a tank at the Ingevity chemical plant in DeRidder, Louisiana. Additionally, a potential monitoring panel using zinc reference electrodes was installed on the outside of the tank. The T-6 storage tank is made up of carbon steel with an interior stainless steel liner, and the liner has a Plasite coating over the bottom 4 feet of the tank. There are 4 heating coil inlet and outlet locations above the stainless steel and carbon steel interface.

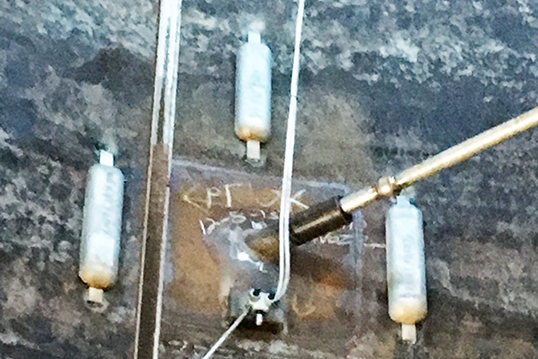

The anodes were installed inside the tank at each upper inlet/outlet location. Deepwater supervised Ingevity personnel while they welded on the flush-mounted anodes. The anodes were installed in 4 groups of 3 each, vertically around each nozzle at the 3, 9, and 12 o’clock positions.

The monitoring system is made up of two (2) V-string zinc reference electrodes (R01 and R02). The reference electrodes are mounted with wire rope clips welded to a C channel. The C channel is welded to the inner tank walls. R01 is located 12” below the upper outlet nozzle and 16” from the anodes on the western inner wall of the tank. R02 is located approximately 7’ from the bottom of the tank and approximately 7’ south of the lower outlet nozzle.

R01 and R02 V-strings are tied together with zip ties every 5’ and routed up and out through the top gap of the tank to a Deepwater monitoring panel. The panel is installed inside of a plastic weatherproof enclosure on the outside eastern wall of the tank.

It was recommended to Ingevity personnel to complete the installation by installing a PVC or similar buffer at the top of the tank to protect the V-string from damage caused by cable vibrations. It will take approximately 6-8 months for polarization to occur. After polarization, Ingevity should continue to monitor the tank CP potentials from R01 and R02 at an interval that falls in line with other tank monitoring activities or every 1-2 weeks.