Dock and jetty cathodic protection

A number of options for docks and jetties

Depending upon the variables involved, including the length of life extension desired, water depth, harshness of the environment and the potential for damage from typical dock activities, Deepwater has several retrofit designs to match virtually any scenario. The optimal design is sometimes a combination of anode types.

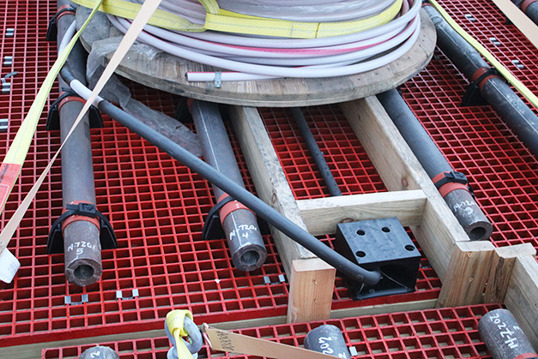

Timber Anode Sled

Shallow water impressed-current anodes