Software for use with the Deep C Meter™

Survey™ is designed to make cathodic protection surveys quick and easy. It comes free with every Deep C Meter™ 3000AD purchased. The software can work in multiple three modes, to support any survey requirements:

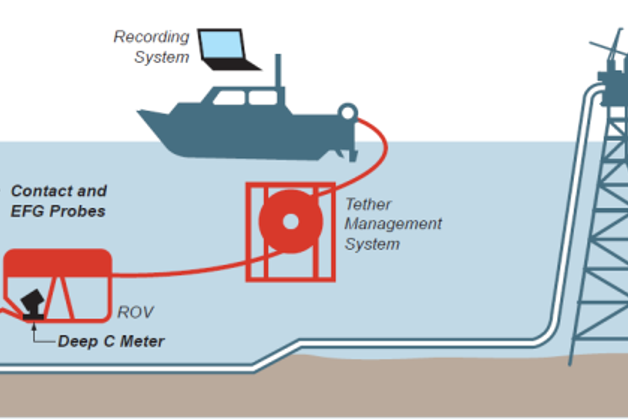

> Traditional Stab + EFG - The ROV take stabs and EFG readings, but no remote electrode readings.

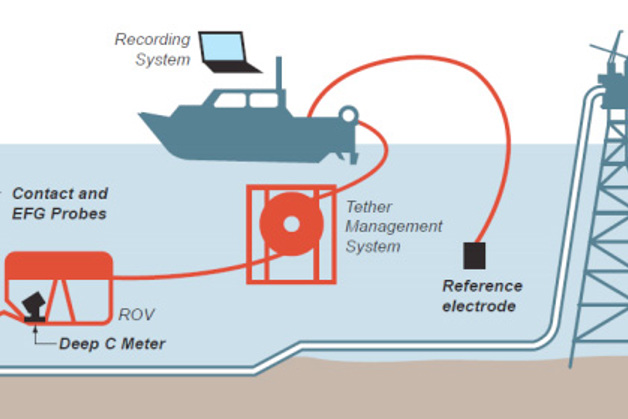

> Remote electrode - The ROV takes stabs and EFG readings. In between stabs the ROV also takes remote variance measurements with a remote electrode deployed over the side of the vessel or attached to the ROV’s TMS.

> Swain™ meter mode - for use with the underwater clamp-on ammeter.

Additional features

Import telemetry data

Import ANY data-stream to be recorded in the software alongside the CP readings (telemetry, etc.)

Remote variance

Virtual potential in real-time (last calibration + remote variance), just like other survey systems (NOTE: this reading is not an actual CP potential)

Time machine module

Allows the user to select any data point from the last 30 seconds (data sampling rate: 2 per second). No more clumsy button pushing at the moment of stab.

Pre-load survey

Pre-loaded event comments allows you to enter stab locations and survey points customized to your assets ahead of time. Just tick them off as you survey.

Logs all the time

100% logging all the time (while the software is on, data is being recorded) - no chance for user error.

CSV output

A quick .csv output of event log (stabs, spot readings) allows for stab surveys to be completed during the survey.

Pipeline survey modes

Stab survey

The stab survey method records the actual steel potential with periodic stabs every 1 - 3 km. The potential between stabs can be accurately calculated with pipeline attenuation modeling. Deep C Meter ™ software in Stab Survey mode records events and exports a completed survey for the engineers to model.

Remote electrode survey

The remote electrode method calibrates a remote reading with periodic stabs of bare steel along the pipeline. The data is then aligned in post processing. Not as accurate as a stab survey, but required in some regions. Deep C Meter™ software in Remote mode outputs stab events and the complete set of readings from the proximity electrode for processing.

Video: Quick Start - Remote Electrode Survey Mode

Shop Polatrak® online

Polatrak® online store

Shop online for all Polatrak® instruments for divers, ROVs and topside deployment with details about kit contents, spare parts, service, rental information and more.