Cathodic protection modeling

Quick, cost-effective and accurate predictive modeling

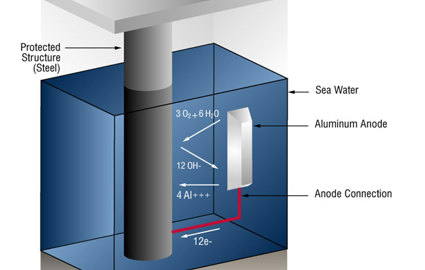

Deepwater offers FEM/BEM computer modeling of cathodic protection design to help verify a system's potential distribution and lifetime, evaluate special-case scenarios, determine a structure's remaining CP capacity before retrofitting, optimizing a retrofit solution and aiding and optimizing inspection planning. By offering computer modeling along with cathodic protection system design, review and verification, Deepwater provides a quicker, more accurate and less costly alternative to using outsourced vendors for this service.

Predictive modeling examples

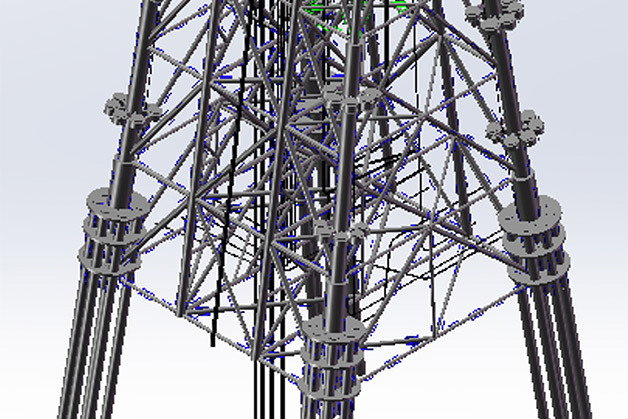

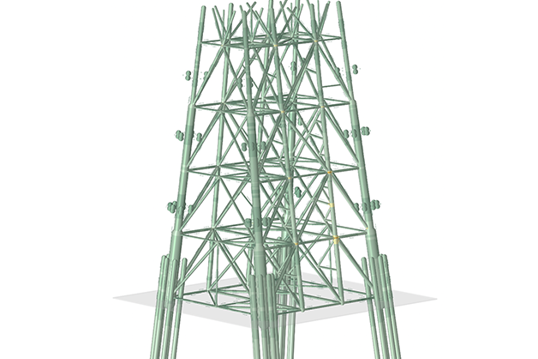

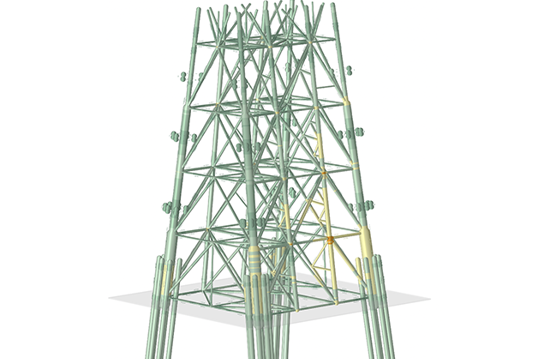

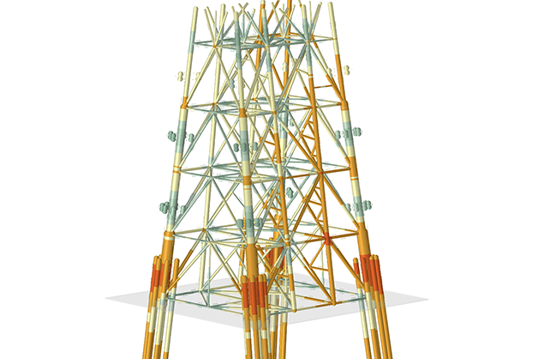

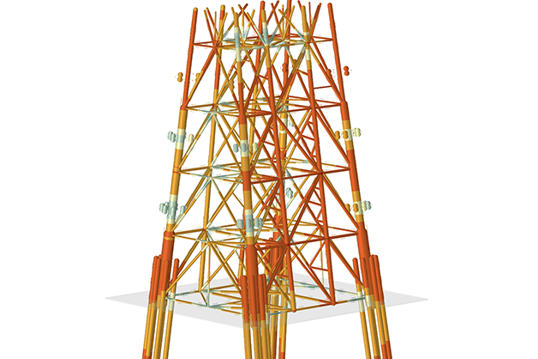

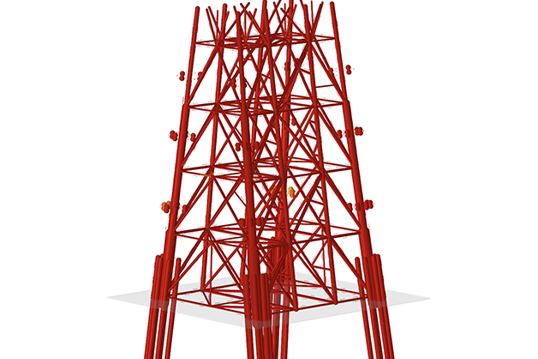

SIMULATION OF END-OF-LIFE FOR JACKET IN NORTH SEA CONDITIONS

The jacket was shown to have acceptable potentials and had outperformed its predicted life from a prior simulation. Of key interest was the necessity and timing of a CP retrofit to goals for the life of the field.

CP MODELING USED TO VERIFY 15-YEAR LIFE EXTENSION ON RISER BASE

Deepwater modeled cathodic protection (CP) of a riser base with 3D to determine whether a CP retrofit was needed. This result was compared to a traditional CP assessment (no modeling) on an identical structure conducted less than a year previously.

Deepwater’s CP modeling for an end-of-life study results in much more useful data than our competitors and is faster and less expensive.

Deepwater’s cost is a small fraction of our competitors’ price for a number of reasons:

– Existing survey data can be used, as a relatively small amount of data points are required.

– Often, the largest expense (50% to 75%) is the time spent on 3D drawings. If you already have 3D CAD files of your structure, we’ll use them, and you’ll bypass the added time and costs.

– Pay for results - not for hours. Deepwater offers its end-of-life study for a much lower price without the endless billable hours that our competitors require.

Types of modeling offered by Deepwater

Asset 3D modeling: We can build a 3D model of your asset if you need one.

CP modeling report: Used as a CP end-of-life assessment. For the greatest cost savings, we'll use your existing 3D models.

CP model update: Update your earlier modeling report with annual inspection data to confirm and refine the estimate from the 'end-of-life' report.

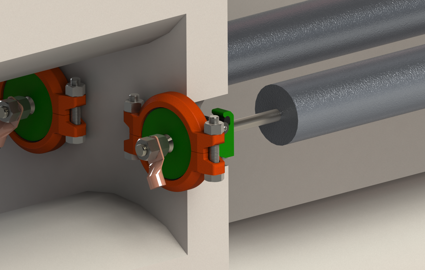

3D Design verification: For retrofit or new-build structures to verify CP coverage, distribution of current, prevention of over-polarization, etc. Used by Deepwater during a CP retrofit to ensure optimal protection.

Additional reasons to use Deepwater’s CP modeling services

Deepwater’s investigation services: We have offshore personnel if further onsite data are required.

Offshore probes: Deepwater is the manufacturer of Polatrak® CP probes, which are some of the world’s most widely-used subsea CP survey instruments.

Watch the video

Low cost and quick turnaround mean little unless the resulting data have high value

Deepwater’s predictive modeling methods also provide more reliable data than our competitors. Here’s a brief description of our process:

The first step for elaborating a predictive model is to calibrate the model using measurable data of (for example) potential, current and anode mass remaining. Existing data from past surveys are taken to calibrate the model in respect to matching the measured potentials.

Sometimes only a few points can be identified consistently across survey years and are used for model calibration at specific points. Other data are presented to demonstrate that the model is producing feasible outputs across the structure.

This method of modeling is different from competitors’ studies based on best-guessing the accrued average current density and fixing that over time, so that for various studies the current density is re-assessed and manually modified and the estimated retrofit requirement date changes as a result of an increasing current density.

Traditional CP retrofits rely on an abundance of conservatism that drives up costs and may not provide optimal protection. Better options are available to extend the life of any offshore asset and Deepwater’s CP simulation methodology helps to identify, understand and choose the best one for your situation.

Key points

Expert team: Our team of modeling experts are supported by Ph.D-level electrochemists, CP specialists with collectively dozens of years of offshore expertise and Deepwater's data from hundreds of subsea inspections.

Better predictions: Predictive modeling enables our engineers to analyze what-if scenarios concerning coating breakdown, loss of anodes and other structure-threatening possibilities. We can also make more exact predictions on anode consumption and end-of-life scenarios.

User-friendly: Utilizing 3-D structural software with a user-friendly interface makes modeling significantly more efficient. With our live link to CP software, we can easily import or generate structural geometry for our models. For even greater efficiency, we've established a library of in-house retrofit and CP options.

Optimized designs: Modeling allows optimization of CP retrofit anode distributions, GACP and ICCP hybrid systems and sled designs that minimize anode current interferences.