Brent pipeline

Pipeline cathodic protection retrofit using anodes built into stabilization mattresses

Deepwater supplied Retromats™ and RetroClamps™ to protect 12 km of pipeline for 15 years

In 2010, a cathodic protection survey showed that two sections at each end of a 148 km pipeline in the North Sea had “low structure potentials”. In 2012, Deepwater installed CP retrofits on those sections, which were each at a depth of about 100 meters. The pipeline to be protected was 36” nominal pipe with a 7mm asphalt coating and a 2.25” thick concrete weight coat. To boost the cathodic protection, a total of 16 Retromats™ and RetroClamps™ were used in two groups of eight; these were placed within “hot spots” at either end of the pipeline, each 6 kilometers long.

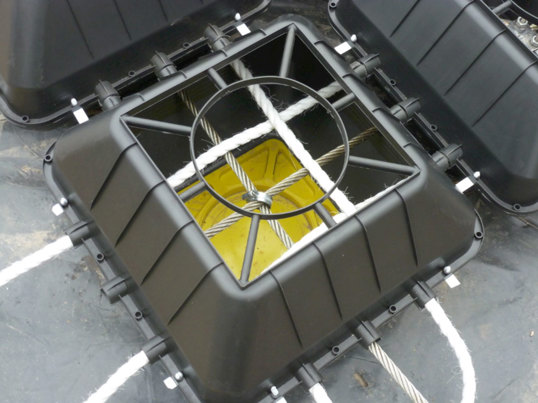

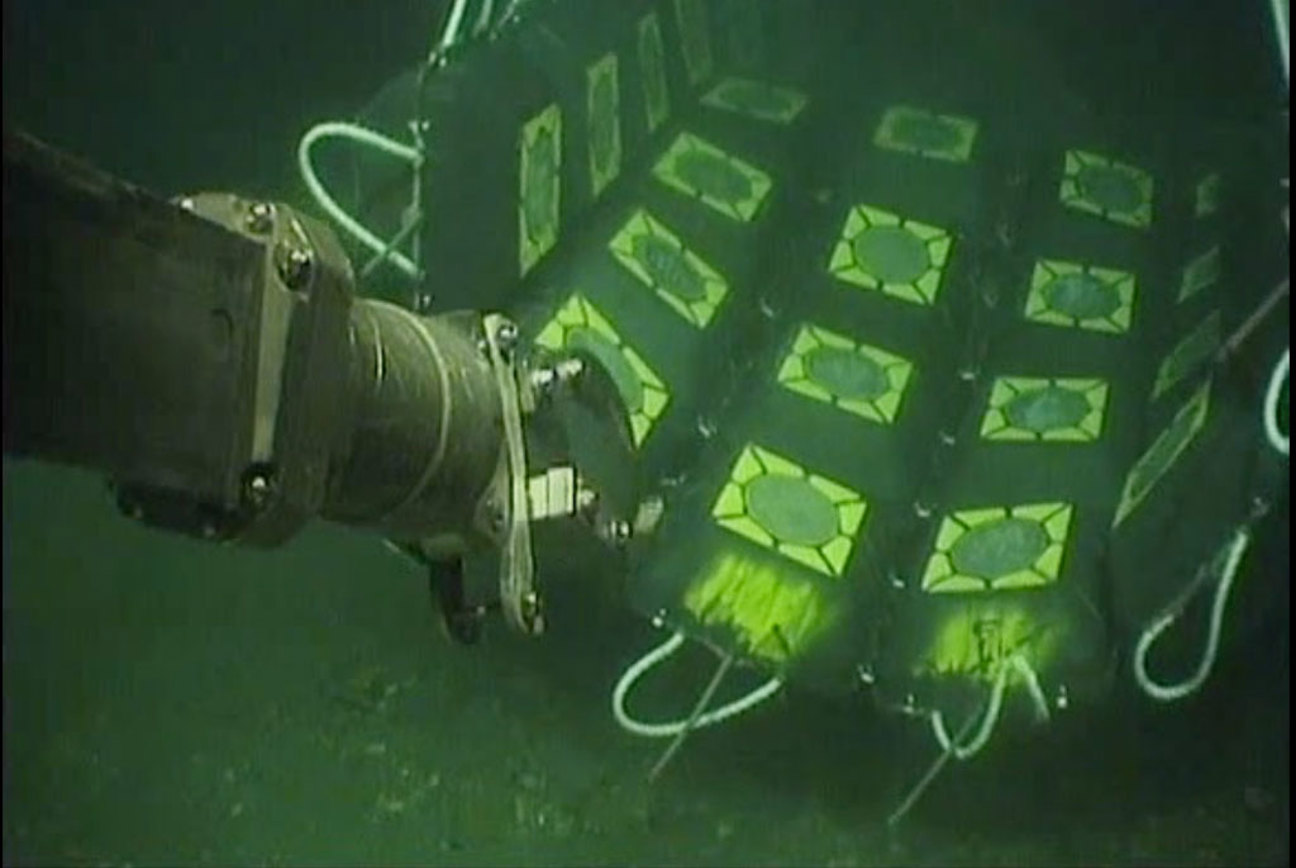

Deepwater’s Retromats™, which are concrete stabilization mattresses with anode arrays cast inside, were used as the CP source. They were delivered as empty shells and anodes, and were assembled on-site by local crews. The shells were snapped together, the cables were connected and concrete was poured to embed the anodes within the mat.

Installation

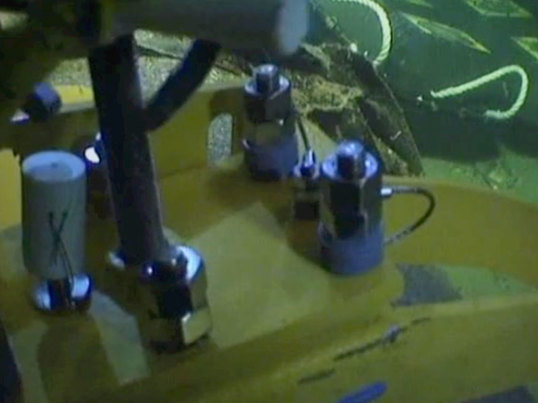

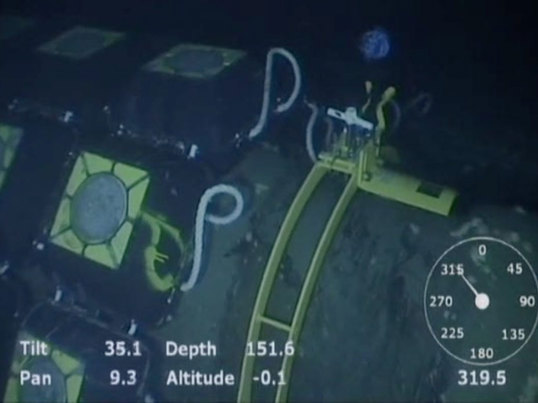

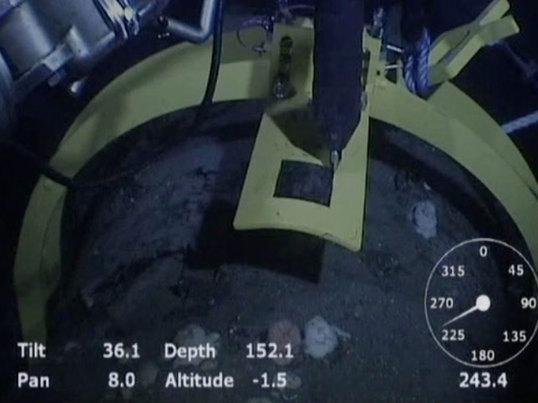

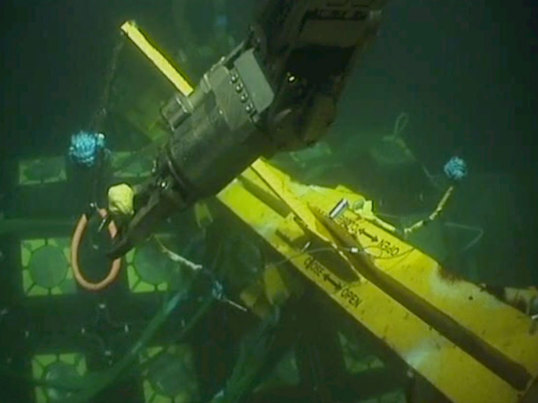

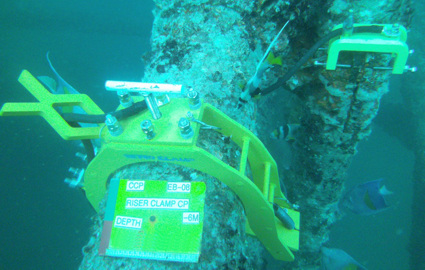

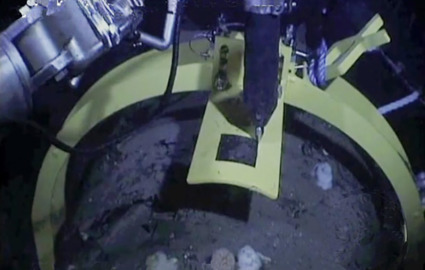

The Retromats™ were transported via work boat and deployed using ROVs to position the mats into place. The mats were electrically connected to the pipeline with RetroClamps™, which were also placed by ROV. The clamps use a screw-in bit that penetrates the concrete coat without harming the pipe. A continuity check confirmed that the electrical connection was made and that the pipeline was protected.

The installation was problem-free, completed on time and within budget, and the installation contractor stated that the Retromat™ installation didn’t cause any undue concerns. The Retromats™ will provide fifteen years of protection for the pipeline.