CP Design

Cathodic protection design services and third-party review from NACE-certified engineers

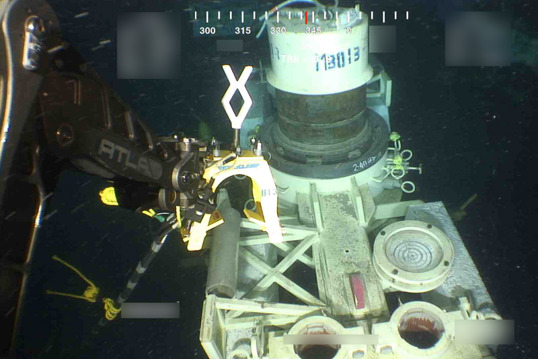

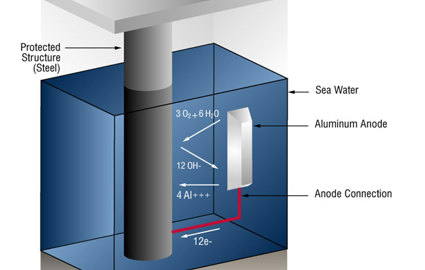

In addition to new-build designs according to NACE, ISO and DNV standards for traditional assets, Deepwater specializes in protecting complex subsea equipment and designing retrofit anode systems for aging assets in need of life extension.

CP design codes for new assets

Subsea pipelines

Anode system design for new pipelines also is strictly governed by industry-accepted design codes DNV RP-F103, ISO 15589-2 and NACE SP0169-2007

For subsea equipment

For subsea production equipment or anything else in deep water, the existing standards are modified by the following: NACE 7L192

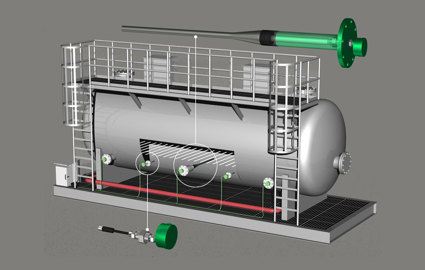

Tank internals

For CP Systems installed inside tanks and process vessels, the following standards are used: API 561

Platforms and floaters

New platforms, TLPs and floating production are all designed to one of the established design codes: DNV-RP-B401, NACE SP0176-2007 and ISO 19906