Level 1 inspection

Deepwater began conducting platform inspections in 1986, just before the BSEE instituted a “Level I” inspection requirement.

Since that time, we have continually focused on improving the value of our inspection services. The basic format for most Level I surveys in the Gulf of Mexico was developed by Deepwater, and we are again driving innovation with our risk-based inspection procedures and online reporting delivery database. These tools help operators focus their inspection spending where it’s needed most, which ensures staff safety and controls costs.

NACE certified inspectors

All of Deepwater's offshore inspection teams are led by NACE-certified corrosion experts with many years of offshore experience. All inspectors have passed OCAT, Helix, SafeGulf, fall and rescue, and of course, NACE CP level 1 training.

Online report delivery

Deepwater's ARMS system delivers reports online to customers and keeps historical files organized and quickly available in our library.

Specific report results are input into the database for queries into individual assets or types of issues reported. An asset integrity manager can quickly find where s/he has problems reported across an entire fleet of assets.

Asset management

ARMS (Asset Reporting and Maintenance System) also has an asset management section, which allows asset owners to keep all relevant documentation and other files of interest in one place.

Store AS-BUILT drawings, asset data, overview photographs, inspection procedures online and accessible to anyone set up with access and a user account. Customers can control access for all of their employees.

Inspections performed

Long track record

Since 1986, Deepwater has filed tens of thousands of Level 1 inspection reports.

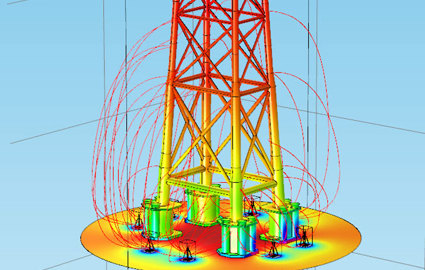

Topside elements

The topside section of Level 1 from Deepwater covers all of the standard level 1 components: In-service paint inspection Structural damage Corrosion safety (handrails, walkways, boat landings, etc.) Process equipment external inspection Erosion corrosion site selection

Coast Guard elements

Deepwater covers all items under the jurisdiction of Coast Guard regulations on the OCS (33 CFR 140.103, Title 33, Subchapter N, Outer Continental Shelf Activities, Parts 140-147). Deepwater ensures owners & operators comply with required documentation (form CG-5432).

Transformer rectifiers

When a structure has impressed current cathodic protection installed, Deepwater's inspectors take special care of the rectifier portion. Monitoring the output and maintenance of the rectifier is critical for the corrosion control system. Each is tracked as a separate asset in our online database,

Did you know...

Deepwater manufactures and sells our inspection instruments. Polatrak® brand probes are even favored by our competition.

CP survey

CP potential survey performed on main structure, risers and vessel internals

Riser survey

Riser inspection includes monitoring CP readings at both ends and close attention to continuity readings.