I-Rod 28 Year

I-Rod® 28 years after installation

The following images were captured in 2017 during a routine topside inspection of the first offshore structure where I-Rod® pipe supports were specified (see the 13-year study for photos of the same support material in 2002). The system was installed in 1989 for less than $10,000 USD. These photos show the long-term success of the system at 13 and 28 years when Deepwater Corrosion Services, Inc. visited the structures for inspections in 2002 and 2017.

2002: 13 years after installation

This fuel gas line is always wet (the green coloration is mold) and the beam paint system has failed, but no corrosion has occurred at the pipe support.

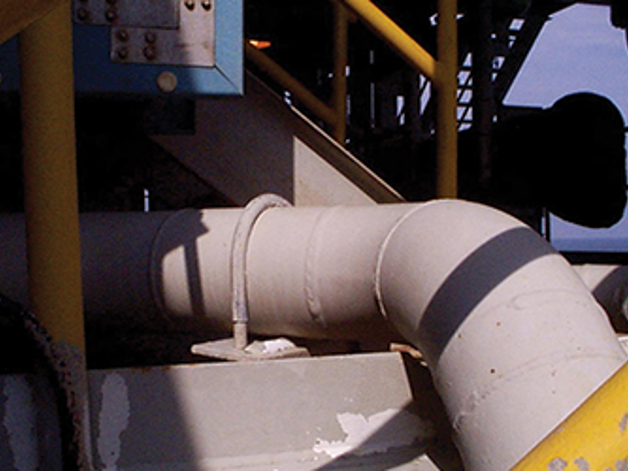

2017: 28 years after installation

28 years after installation, the fuel gas line shows minor paint failure at the support but the I-Rod is still intact.

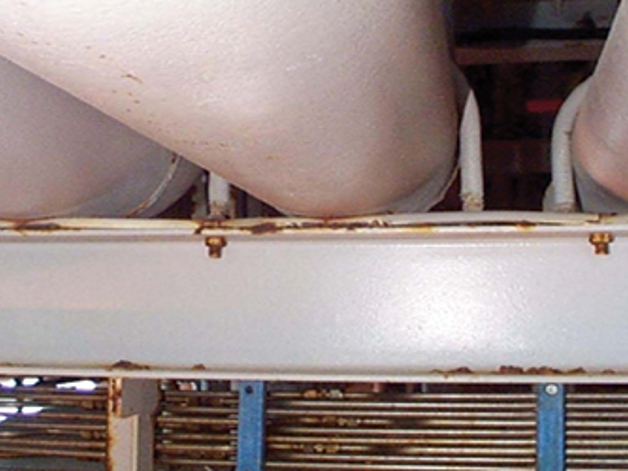

Another pipe that stays wet, as evidenced by the mold and mildew on its surface. At 13 years after installation, the support was performing well.