Technical Paper

Early coating failures on offshore platforms

by James N. Britton (2004)

Abstract

This paper describes several common modes of early coating failure that lead to corrosion problems on offshore platforms. Symptoms are analyzed and solutions are presented. The work is based on the examination of two offshore platforms in the Gulf of Mexico that had been in service for less than 18 months.

Introduction

This paper provides some examples of how offshore paint systems in atmospheric service fail to deliver protection for their full life expectancy. For this study, we have selected two typical fixed drilling/production platforms in the Gulf of Mexico as case histories. Both deck facilities were fabricated on the US Gulf Coast at different fabrication yards. The jackets and decks were actually set in place in June of 1997. Our investigation was performed in November of 1998; the facilities had been offshore for only 17 months at the time of inspection.

Why did failures occur?

Analysis of the following examples will show six basic reasons for the poor performance of coatings. Some are easy to deal with and others require much more effort to repair. Often it is one or more of these causes working together to produce the end result. In each example, I have attempted to propose a solution that is workable.

The six causes are as follows:

1. Poor surface preparation (especially surface cleanliness).

2. Poor coating application.

3. Poor or inadequate inspection.

4. Poor specifications (both construction and coating).

5. Poor component design.

6. Murphy's Law

Failure 1: Beam edges

Figure 1. illustrates a problem that was found in many locations on the structure, in particular where plate gussets had been welded to I-Beams. The sharp edges of the plate sections are particularly difficult to coat. They should have been radiused,which would have facilitated a better application of the coating. However this is not the full extent, nor is it the single cause of the problem.

Inadequate film thickness is a basic problem that is clearly not given enough attention by inspectors, although one would expect applicators to understand the requirements. The specifications call for a stripe coat that was obviously not applied. This failure will progress rapidly, and undercutting will soon fail the system (2-3 years) to the point that an expensive re-paint will be required.

Solution(s)

1. Select coatings with improved edge-retention characteristics.

2. Ensure the correct application of stripe coats at the beam edges (as recommended by the paint manufacturer).

3. Radius all beam edges to improve retention characteristics.

Figure 1 - Beam edge failure

Failure 2: Stainless steel tubing attachment

Figures 2-4 illustrate a common problem for structures in the Gulf of Mexico: the use of stainless steel bands to attach stainless steel tubing to process equipment, which in this case is a pressure vessel. The primary failure is initiated when the band on the buckle punctures the paint film and simultaneously provides a galvanic couple with an undesirable area ratio. Corrosion progresses rapidly and soon undercuts the adjacent film. A secondary failure mechanism begins at the band, where a water-retaining crevice is formed. The paint is softened by immersion service, the film fails and galvanic couple drives a corrosion cell at an advanced rate. The consequences here can be more serious and could lead to rapid pitting of the vessel shell. This is clearly a case of poor design; neither the painters nor the coating are at fault here. The need to route tubing on the vessel should have been anticipated.

Solution(s)

1. Find an alternate routing for the tubing off of the pressure equipment.

2. Provide dedicated structural support points on the vessel for tubing support.

Figure 2 - Stainless banding on vessel

Figure 3 - Buckle puncture

Figure 4 - Galvanic corrosion

Failure 3: ID tags and float level indicators

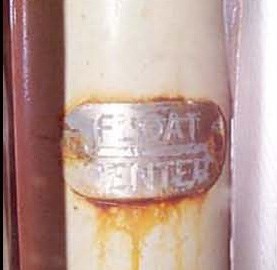

Figure 5. illustrates a common problem around I. D. tags offshore. The item in the picture is part of a vessel level control system. The offending piece is a riveted plate attached to the hydrocarbon-containing cylinder. The notation on the piece is "FLOAT CENTER" above and below a horizontal line. The problem is a complete lack of any coating behind the plate, causing crevice corrosion and a galvanic couple. This mechanism will soon pop off the tag, as corrosion product forces exerted from within the crevice become greater. Perforation of the cylinder is not uncommon, but certainly coating failure will require an expensive repaint. The writer can attest to personally having seen this problem on hundreds of offshore platforms.

Solution(s)

1. Write specifications that prohibit this type of design.

2. Lose the tag and weld on a stripe or remove tag, coat the affected area stencil line.

3. At the very least attach the tab with a seal weld.

Figure 5 - Float level tag

Figures 6-7 show some other examples of I. D. tags causing corrosion problems, but there are some important differences. These tags are made of stainless steel and bear critical information about the part that they occupy a space upon. So, when they pop off into the Gulf, the information lost is a little more important (e.g. more so than "FLOAT CENTER"). The loss of these tags is usually attributed to the aggressive galvanic couple driving the reaction. Progressive coating failure will result at many points in the coating system.

Solution(s)

1. Write specifications that prohibit this method of ID tag attachment.

2. Stamp information on steel doubler plate seal welded to part.

3. Attach tag with SS wire lanyard to part.

Figure 6 - ID tag crevice

Figure 7 - Tag on accumulator

Failure 4: Surface preparation / Poor cleanliness

Some of the examples below can and should be prevented with diligent inspection. The failures will cost the platform operator many tens of thousands of dollars to correct. The paint system will come up way short of design life expectation.

Figure 8 shows the result of poor surface cleanliness, as paint has already disbonded from surface at six o'clock pipe position. Probable cause is that pipe was wet when painted and gravity driven accumulation at 6 o'clock has accelerated failure. This indicates a poor level of surface condition monitoring during the application process and it is likely that more failures will show up in fairly short order.

Figure 9 shows another common problem: Premature coating failure on field girth welds. There are two main contributors here, mainly lack of post weld cleaning and inadequate blast profile. Field welds are difficult to properly blast and clean by their geometry, particularly if access is difficult. There may also be a tendency to want to minimize over blast damage to adjacent painted surfaces. These local failures quickly undercut and spread, soon compromising the entire run of piping.

Possible solutions are to install flanges to minimize field welds. However, pipe flanges provide just as difficult a problem, but at least they can be shop coated. Certainly it is prudent to minimize the number of field welds, but some are always necessary. The best solution is to take the time and effort to protect adjacent surfaces and take additional time to obtain the needed level of blast profile and cleanliness.

Figures 10 & 11 show examples of pin holes at areas of blast medium contamination of the surface.

Solution(s):

The above problems could all be averted with diligent inspection to a well-written coating specification document. Ensure that they have the necessary NACE or appropriate level of certification for the job in hand. Repainting an offshore platform can cost millions of dollars, and a 30 or 40% reduction in expected life translates to hundreds of thousands of dollars in lost asset values.

Figure 8 - Poor cleanliness

Figure 9 - Field weld coating

Figure 10 - Blast medium contamination

Figure 11 - Corrosion at pin hole

Failure 5: Fasteners

Fasteners have always been a problem, and many specialized coatings have been tried and many have not worked well. Post-installed paint films are very difficult to apply effectively because of all the edges and crevices involved.

Figures 12 & 13 show two examples of how fastener coating failure is contributing to a greater problem. The corrosion products, apart from looking nasty, will fail the films onto which they fall and spread the deterioration.

Solution(s):

1. Use quality fastener coatings or use corrosion-resistant alloys. We have seen the best performance from aluminum ceramic coatings, although metallic plated coatings can work if correctly selected for service.

2. Protective caps with inhibited grease fills can work well; ensure that they engage positively on the thread. They are, however, rather expensive, and will require a low level of maintenance to ensure complete protection.

Figure 12 - Fastener corrosion soon spreads

Figure 13 - Fasteners are hard to coat

Failure 6: Pipe supports

These two platforms had done a good job with specifying pipe supports, having specified crevice control systems (Figures 14-15), so the problems found were minimal (Figure 16 below). However, the isolated points where the supports had been omitted do demonstrate how quickly the pipe support problem can manifest itself.

Figure 14 - Crevice control In place with half round thermoplastic rod.

Figure 15 - No corrosion at pipe support

Figure 16 - Corrosion starting where crevice control is omitted

Failure 7: Mechanical damage and drilling operations damage

Figures 17-19 show typical examples of mechanical damage. This type of damage falls under the "Murphy's Law" category, being impossible to avoid completely. The rate at which corrosion will progress will be a function of location of the damage. The most practical solution is to use a soft oxygen barrier type coating to prevent progressive undercutting. Several "green" brands are available that will do an adequate job.

Figures 20-21 show initial failure that has progressed because of drilling mud falling onto structural members and piping. This is another situation that is practically impossible to contain (after all, these are drilling platforms). Regular pressure wash down with fresh water will minimize the problem and the use of basic containment within the well bay will help minimize the extent of the problem areas.

Designers may consider these problems when routing piping in areas where contamination is unavoidable and elect to use CRA piping if an alternate route cannot be found.

Figure 17 - Mechanical damage on vertical diagonal brace.

Figure 18 - Unavoidable mechanical damage

Figure 19 - More mechanical damage

Figure 20 - Drilling mud on members under well bay.

Figure 21 - Breakdown on piping under mud.

Summary: Lessons learned

With the new generation of large floating production facilities, designers and corrosion engineers alike would do well to learn from these expensive lessons. The cost of prematurely repainting a large TLP or SPAR type structure could extend into millions of dollars. The following basic measures will help minimize the risk and maximize return on investment.

1. Commission a design phase corrosion review; this will capture many of the potential problems.

2. Prepare concise and complete painting and construction specifications.

3. Employ only certified inspectors and pre-screened applicators.

4. Utilize proven methods of paint service enhancement such as properly coated fasteners and crevice control systems at pipe supports.

Want to receive an email when Deepwater publishes new corrosion-related technical papers, case studies, and more? Sign up for our Corrosion Newsletter using the form below. You can unsubscribe at any time.