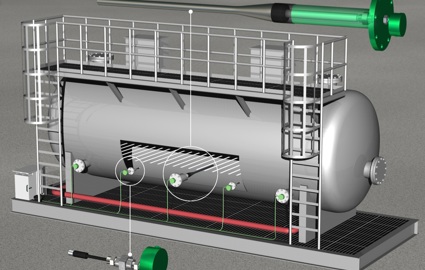

GreenHead™ anode

The GreenHead™ is an improved anode deployment method for sacrificial anodes, and it gives the following advantages:

Green Head Advantages

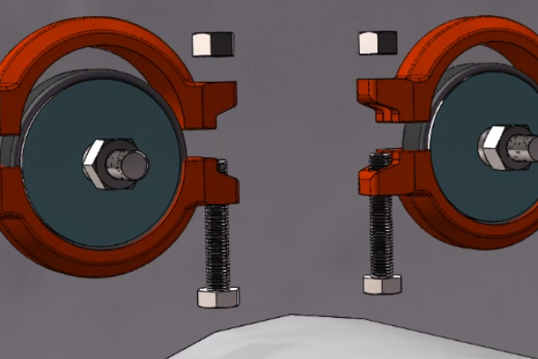

Victaulic cap or flange

A steel Victaulic cap or flanged interface. This is preferable to a plastic cap and ensures there is no risk of leakage. This is a one-time upgrade to the vessel.

Cam-lock receiver

Allows for longer and larger diameter anodes to be quickly deployed, meaning fewer anode changes, no threads, a quick fit positive engagement for the anodes, and money saved.

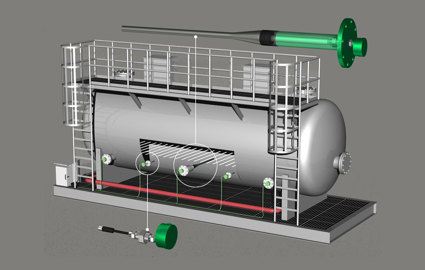

Reference sensors

Deployed with the system, the sensors enable the actual level of cathodic protection on the fire tube to be measured. This allows accurate scheduling of anode replacements.

Lower cost per lb

The anode consumable is lower cost per lb. because the plastic anode head is eliminated and the casting is optimized - no waste.

Most of the systems we have measured do not provide adequate initial current to achieve a polarized condition, and in these cases one of two things happens:

1. The fire tube or vessel experiences corrosion.

2. The anodes require frequent replacement - usually more than once a year.

Anodes need to be longer and slender in order to work effectively in these tanks; large block anodes do not provide sufficient current and are not recommended. Most treaters are equipped with 4” Victaulic nozzles for insertion of anodes.

Many years ago, plastic heads were designed (Red & Blue) to interface with these nozzles and provide electrical isolation of the anodes, such that the current output into the vessel could be measured. These are still in wide use today even though they have three fundamental drawbacks:

Green Head v Blue Head

Green Heads

Green heads have a leak proof connection point - even when the anode is fully depleted. Green head has a larger anode, 100% of which is exposed and working to protect the tank and fire tube. Green head will provide 30-50% longer life and is guaranteed to fully arrest corrosion on the fire tube.

Blue Heads

They are prone to leakage as the expanding anode corrodes and splits the cap. They cover about 5lbs and 8” of anode material which reduces current and wastes money. They restrict the diameter of anode that can be deployed to 3” ensuring that frequent replacement is required.

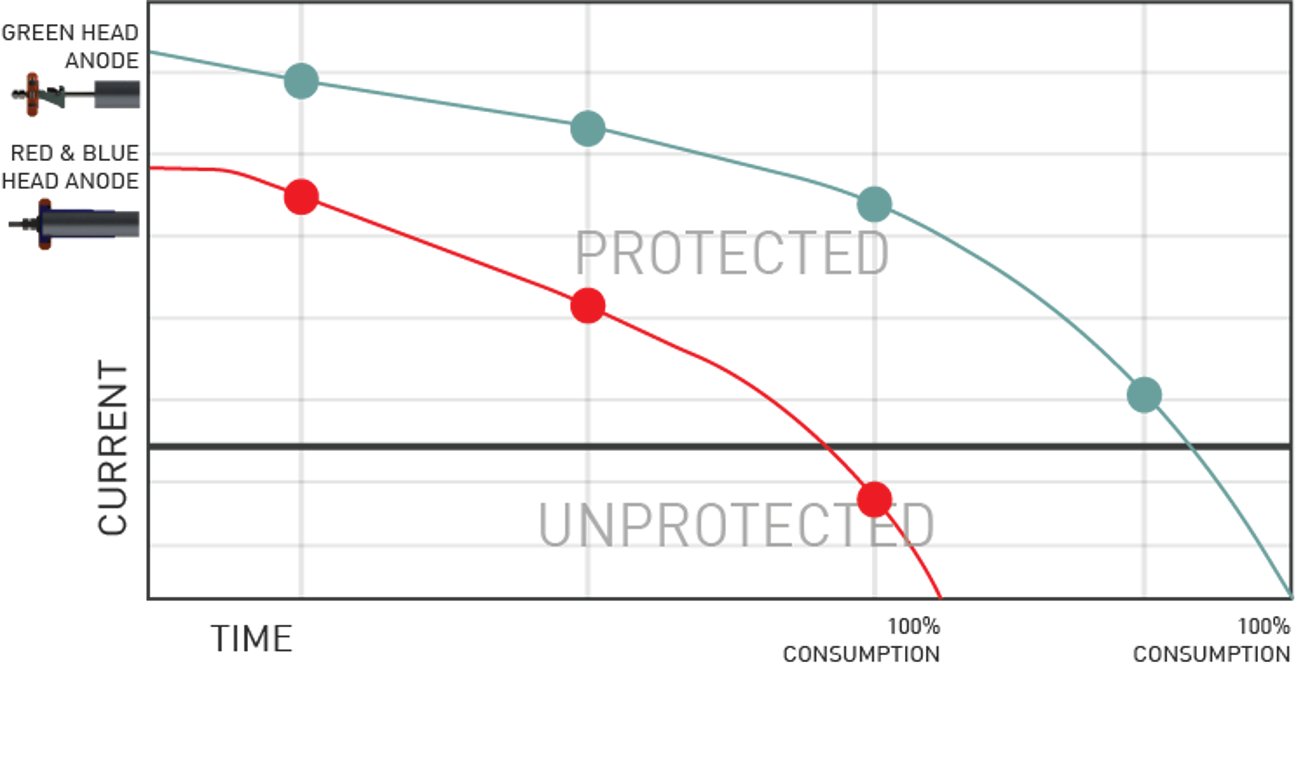

Anode Current vs Consumption comparison

Blue Head = Split Head

After the exposed portion of the aluminum is gone, the anode material inside the Blue Head cap will eventually corrode. Buildup of corrosion product will split the plastic and cause leaks

Easy and cost-saving installation

The Green Head can be installed quickly using hand held tools, and after each sacrificial anode is depleted, a new one can be fitted quickly to the existing anode receiver.