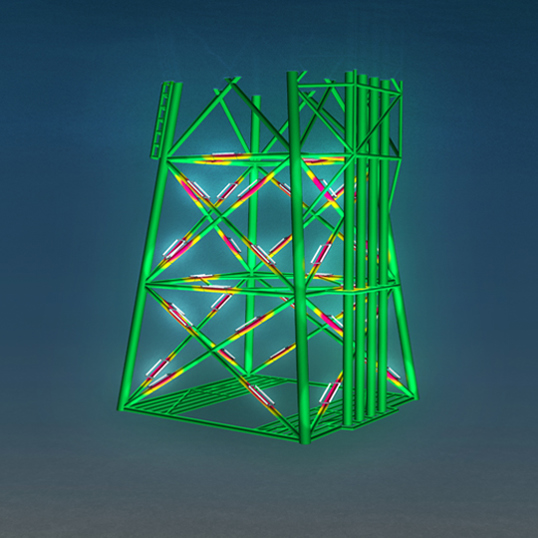

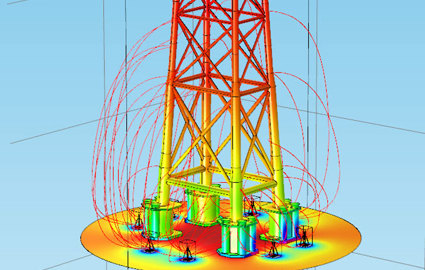

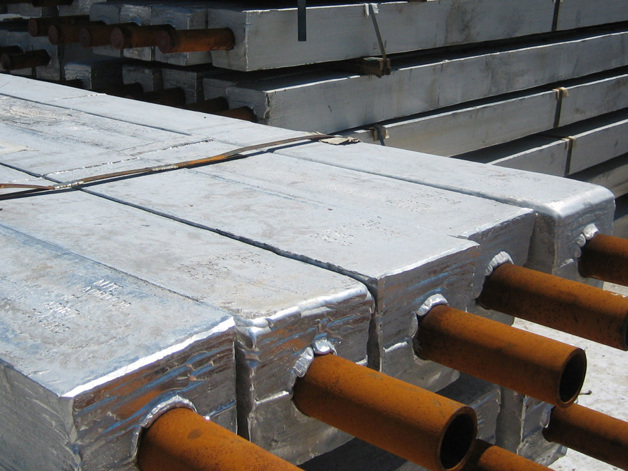

Platform anodes

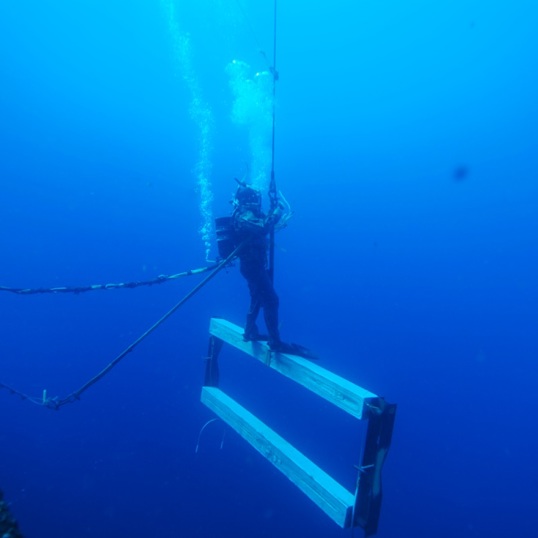

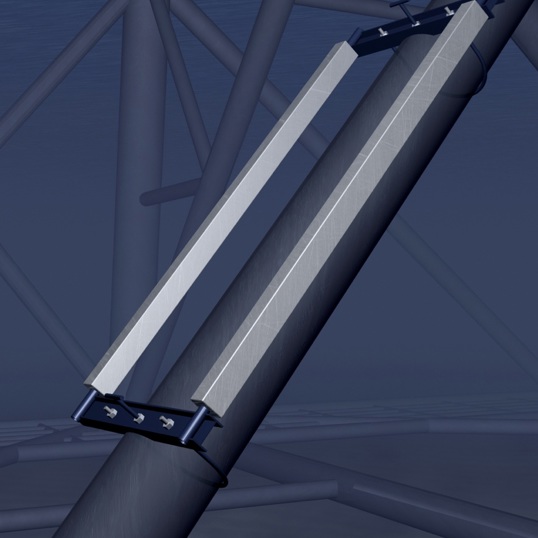

Deepwater’s aluminum anodes are designed specifically for the offshore oil and gas industry.

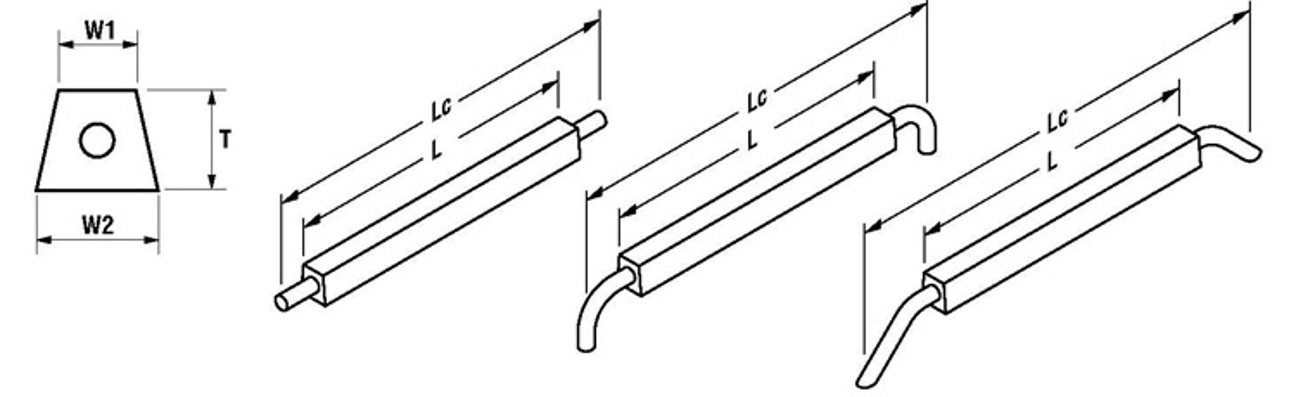

Deepwater's aluminum platform anodes are cast in low-iron, high-purity aluminum alloys and can be manufactured in a wide variety of configurations for new construction or retrofitting. Most standard configurations are available. In addition to these, Deepwater can cast anodes with bulk trapezoidal cross-sections to any specifications required.

Dimensions