Technical article

IMR Heaven - IMR ready retrofittable cathodic protection system for offshore brownfield fleets

by Jim Britton

Introduction

Despite the decreasing number of structures, the offshore brownfield infrastructure in the Gulf of Mexico remains a significant energy resource. Some key things have changed in recent years, however:

- Integrated IMR (Inspection, Maintenance & Repair) programs offer a cost-effective model to maintaining aging assets. This is achieved by integrating a range of offshore tasks to a single vendor for a period of time, thus optimizing vessel and diving resource costs.

- Many structures are now approaching the end of their useful lives.

- The majority of structures have a permanent “for sale” sign on them.

Increasingly robust regulatory oversight, and the need to maintain structural and containment integrity on this infrastructure, cannot be ignored; but with a low commodity price, budgets are stretched.

Deepwater met this challenge by developing a low-cost, modular, retrofittable sacrificial anode system called RetroLink™. Like all Deepwater solutions, this is elegant in its simplicity, reliability, and flexibility. To date, the technology has been successfully applied to approximately 750 offshore structures in the Gulf of Mexico and worldwide.

What is a RetroLink™?

In order to achieve our design objective, we needed an anode system that had the following attributes:

- Able to deliver high current for a 5-6 year life

- Simple installation with no subsea assistance

- High degree of mechanical integrity

- Consistent electrochemical performance

- Low drag and good hydro-dynamic performance

- Modular design (field adaptable) and lightweight

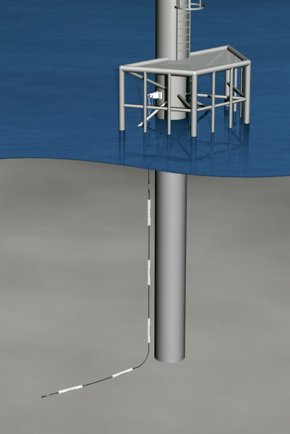

Figure 1 - RetroLink™ was born

There had been several “anode string” concepts in the past that sought to meet the above criteria, most of which suffered premature mechanical failures. We, too, had to engineer out these weak points:

- Suspended strings with trapezoidal anodes that had poor hydrodynamic response

- Many mechanical links between anodes with copper cable jumpers

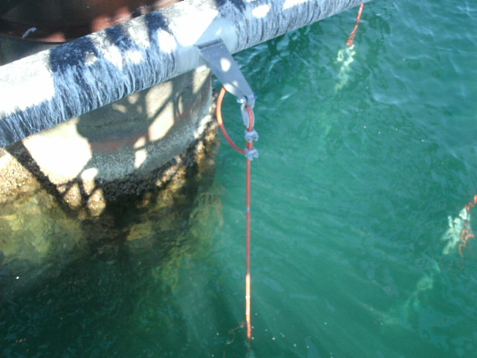

Figure 2 - Poorly designed topside suspension hardware

Figure 3 - Poorly designed suspension systems do not fare well in rough seas

What we designed was a continuous string of anodes, cast directly onto a heavy steel wire rope. The size, number, and spacing of the anodes on the string was designed to optimize current output and minimize mutual interference; while providing the desired lifetime. The cylindrical geometry of the castings and mold design ensure core centrality, enhanced hydrodynamic performance and anode utilization efficiency. Deepwater partnered with the foundry experts at Houston Anodes LLC. to perfect the mold designs and casting protocol in order to prevent internal gas cavities that would be normal in an anode of this construction.

The result is RetroLink™ (Fig. 4)

Figure 4 - The result is RetroLink™

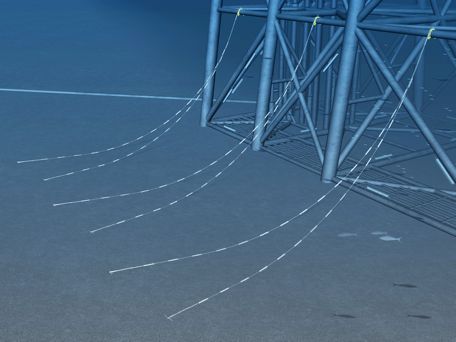

The heavy wire rope used in the manufacture provides superior mechanical properties and has sufficient cross section to act as the conductor. Early designs used trapezoidal section anodes, but these failed due to excessive deflection in the water column and interference with the structure. The RetroLink™ is always installed with at least two anodes in contact with the seabed (Fig. 5). This helps stabilize the string in high current situations and prevents the string from being picked up into the water column.

Figure 5 - The trailing anode stabilizes the string

Figure 6 - Typical RetroLink™ installation showing coated splash-zone lead

In order to make the design life, it is important that the splash zone area is protected (galvanized rope would fail in 2-3 years). To achieve this, we use a polyethylene jacketed leader rope. (Fig. 5)

What has been achieved?

The first RetroLinks™ were installed in 1996 to retrofit mooring chains on an FPSO in West Africa. The following year saw the first platforms fitted in the Gulf of Mexico. Since August 2017, we have installed 3,252 anode strings on 753 structures for 30 different operators.

With an installation time of 1 hour, 7 minutes (per link), and a total offshore time of 2 hours 9 minutes, this is the best CP maintenance value proposition on the market.

On average, these systems have been lasting 6-7 years, with an 85% survival rate through the CAT 4 & 5 Hurricanes in the Gulf of Mexico between 2005 and 2008. This led to a significant uptick in activity, and in the four years following these storms (2009 – 2012), we retrofitted 488 structures with the technology; all of which have delivered the design life expectancy.

What’s happening now?

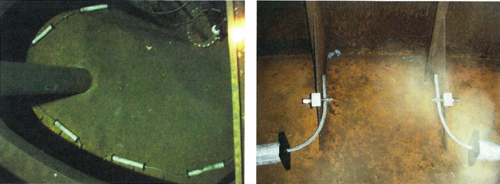

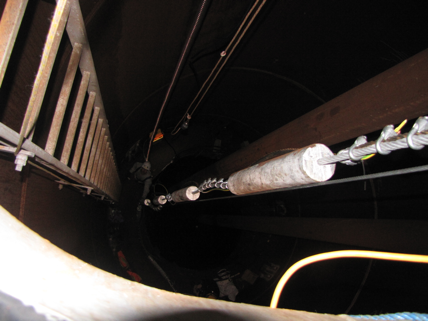

The RetroLink™ is such a versatile device that we are seeing many different applications of the technology. A number of systems have been sold to protect storage tank internals (Fig. 6). The system has also successfully eliminated hot work from internal compartments in floating production systems (Fig. 7). Internal spaces of offshore wind turbines, (Fig. 8) and multiple applications to protect inshore infrastructure (docks, harbors and piers), have been realized (Fig. 9). They have even been used for small diameter pipelines in the wetlands.

Figure 7 - Links ready for installation in storage tanks - they sit on the floor

Figure 8 - Links in a ballast tank on an offshore floater

Figure 9 - Installing links on the inside of a wind turbine monopile

Figure 10 - Installing links on the inside of a wind turbine monopile

Figure 11 - Installation on docks and dolphin structures

The early systems were limited to around 85 ft. (26 M) of water, as this was the optimum length for relatively even current output from all anodes on the string. We began installing the links subsea to address larger platforms. The links were connected by divers to a deep horizontal frame above the seabed; the systems performed very well. Each string was able to deliver a sustainable 8-10 amps. We called this type of installation “Skirt Links”. (Fig. 10)

The latest innovation is to, using only topside installation, reconfigure the links onto longer arrays, with longer leaders, to address even deeper platforms. We recently completed a retrofit of a platform in 207 feet. The original CP system was in the low (-) 0.700 V potential range. The customer wanted a quick, low cost fix, and was willing to accept more risk of future system repair. The system of 44 links was installed in 46 hours with no subsea intervention, and the platform was left fully protected with potentials in the low (-) 0.900 V range. We call this method “Deep Links,” and it has significant cost advantages over Skirt Links. However, Skirt Links may still offer a viable option in some situations where divers or an ROV are required for other subsea activity.

Figure 11 - RetroSkirt configuration

Summary

The RetroLink™ is one of the most versatile anode systems on the market. It can be cast in either aluminum or zinc based alloys. Deepwater has gathered the expertise to apply this anode system to a wide variety of CP projects, and it brings brownfield life extension costs under control while providing predictable and reliable service.