WHITE PAPER

Why these 5 common pipe support designs fail

Various common pipe support designs forget a very simple fact: Crevice corrosion can quickly cause dangerous leaks.

by Steve Young

Support #1: Bare I-beam

1. Bare steel beam or angled support

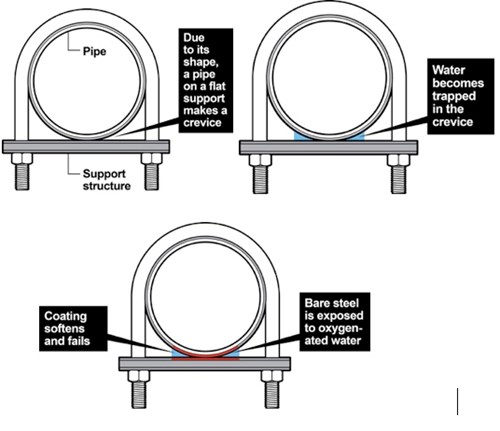

When a pipe is supported by a bare beam or angle, a crevice is formed where the pipe comes into contact with the support (see diagram). Condensation, rain, wash down or similar conditions where moisture is in contact with the pipe cause moisture to be drawn by gravity into the crevice where it becomes trapped. Once the water is trapped in the crevice, it begins the process of softening the coating on the pipe until the coating separates from the bare steel. As soon as the bare steel is in contact with water, the corrosion cell is formed and inevitable pipe failure is only a matter of time.

Crevice corrosion mechanism

Support #2: Rubber pads on an offshore platform

2. Rubber and neoprene pads

For many years, rubber pads have been misguidedly specified in the original design of pipe supports. The misconception is that if this type of pad is installed between the production pipe and the metal support, a galvanic cell cannot be formed and this will eliminate the cancerous corrosion from damaging the production pipe. Unfortunately, this is patently untrue. Though there is a need to separate the metal pipe from a metal support to eliminate dissimilar metal contact, rubber has a few characteristics that actually create a bigger problem than they are intended to solve.

Rubber has a very low compressive strength and breaks down, becoming hazardously porous in a short amount of time. When rubber is put under a load, the pad will depress and create a curved area. The curved area is simply a larger crevice than if the pipe were sitting directly on the steel support and the corrosion problem is exacerbated. The larger crevice traps more water, keeping it in contact with a larger part of the production pipe. The compressed and porous rubber breaks down, absorbing and holding even more water and setting up the same corrosion cell discussed above. Again, as soon as the bare steel is in contact with water, the corrosion cell is formed and failure is inevitable.

Support #3: Metal guides on a pipe at a terminal

3. Metal pipe guides

Metal pipe guides are often used on pipelines where movement of the span is anticipated. That movement may be a result of thermal expansion and contraction, start up and shut down sequences or vibration of the pipe during normal operation. The problem with choosing metal as the guide is that damage can and will be caused when the pipe rubs against the metal guide as it expands and contracts or moves back and forth. This abrasive action compromises the coating and exposes the steel to the atmosphere and crevice corrosion cells. This design does not isolate the pipe or protect the coating while instead, it traps water. Supports like these can cause pipe failure in an exceptionally short amount of time.

Support #4: Bare U-bolt on an offshore platform

4. Uncoated U-Bolt

When a pipe is secured by a galvanized U-bolt, there are a couple of issues that can arise. The first occurs during the initial installation of the U-bolt. During the installation process, the rough galvanized surface can damage the coating on the pipe, compromising the protection it provides. The second is after the u-bolt is secured in place. Cumulative movement or vibration of the pipe causes the rough surface of the galvanizing to damage the pipe coating. Once the coating is damaged, moisture will begin to slowly soften the area and cause the coating to separate from the bare steel pipe and the familiar corrosion cell is formed indicating imminent failure.

Support #5: Wear pad at a refinery

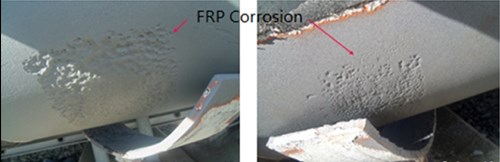

5. FRP / Fiberglass pads

FRP / Fiberglass Pads are sometimes promoted as the ideal “wear pad” solution for protecting the production pipe from the damage caused by pipe movement. This is another costly misconception. While there is a need to protect a metal pipe from rubbing against a metal support, using a curved fiberglass pad to cover a large section of the pipeline. creates a substantially larger crevice than if the pipe were sitting directly on the steel support. The crevice holds water against the pipe, softening the paint and establishing the corrosion cell when the coating is compromised. The second important problem with this type of wear pad is that it is essentially impossible to inspect the space between the pad and the production pipeline for corrosion. The invisible damage that is happening due to corrosion caused by trapped water creates a serious risk for catastrophic failure and damage to a very large section of the pipeline.

Typical FRP corrosion