Offshore drill stack

Cathodic protection levels monitored and corrected on a drill stack in Australia

Drill stack corroding despite anodes in good condition

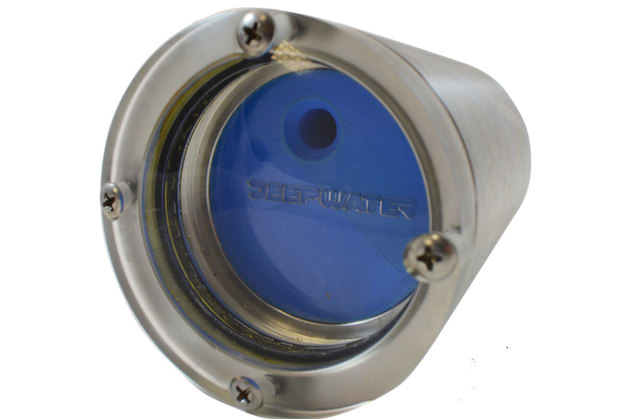

After an initial CP survey on the Osprey Semi-Submersible, continuity readings on the BOP, Deepwater recommended installing the Recap™ Data logger to help determine the cause of corrosion found on the unit.

The Recaps were installed on an I-beam flange with modified RetroClamp. V-strings zinc reference electrodes were located remotely and tied into the Recap's two channels. The client accessed data via USB and emailed it to Deepwater for periodic analysis. The first deployment confirmed that the stack was not protected, especially near electrode V1.

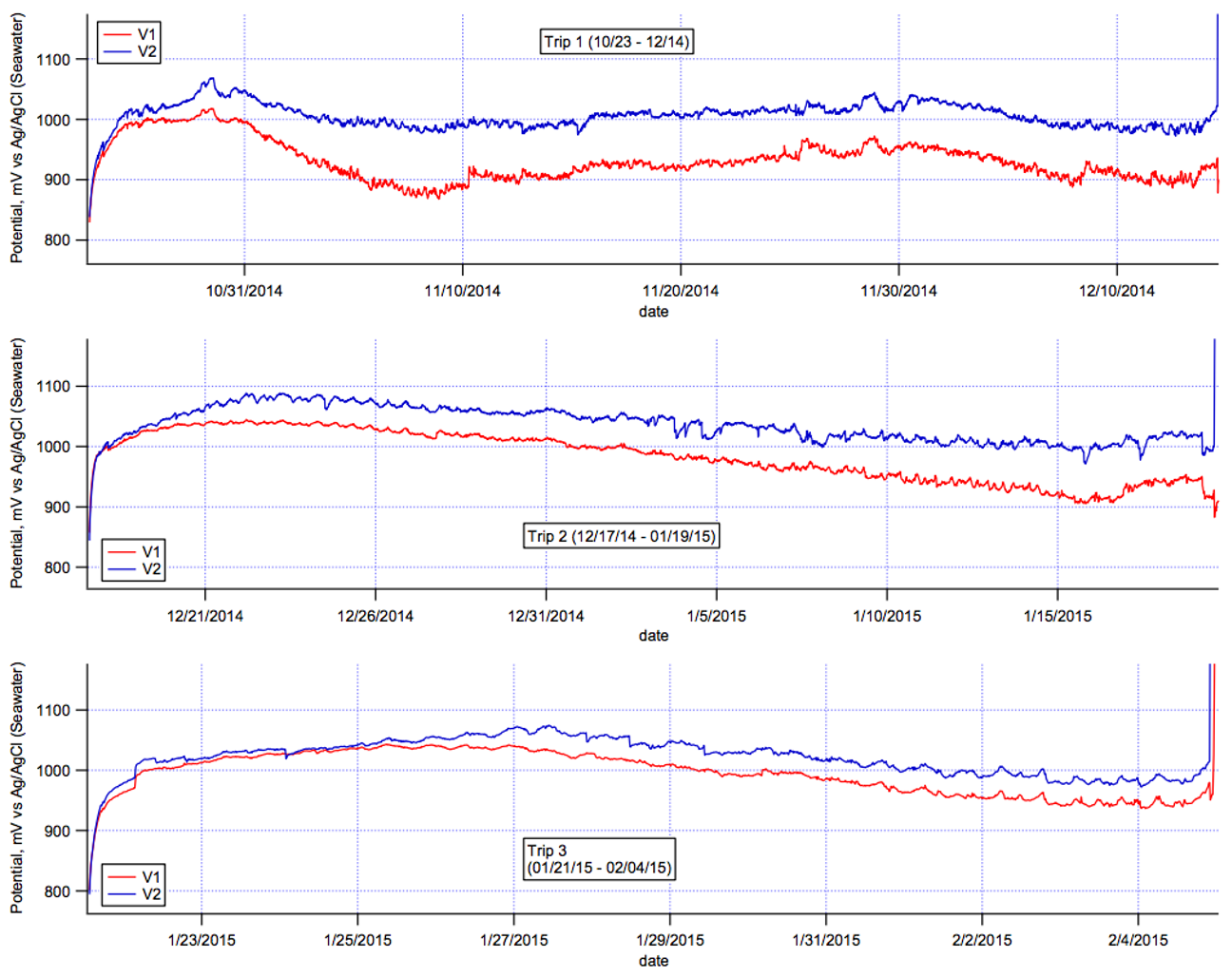

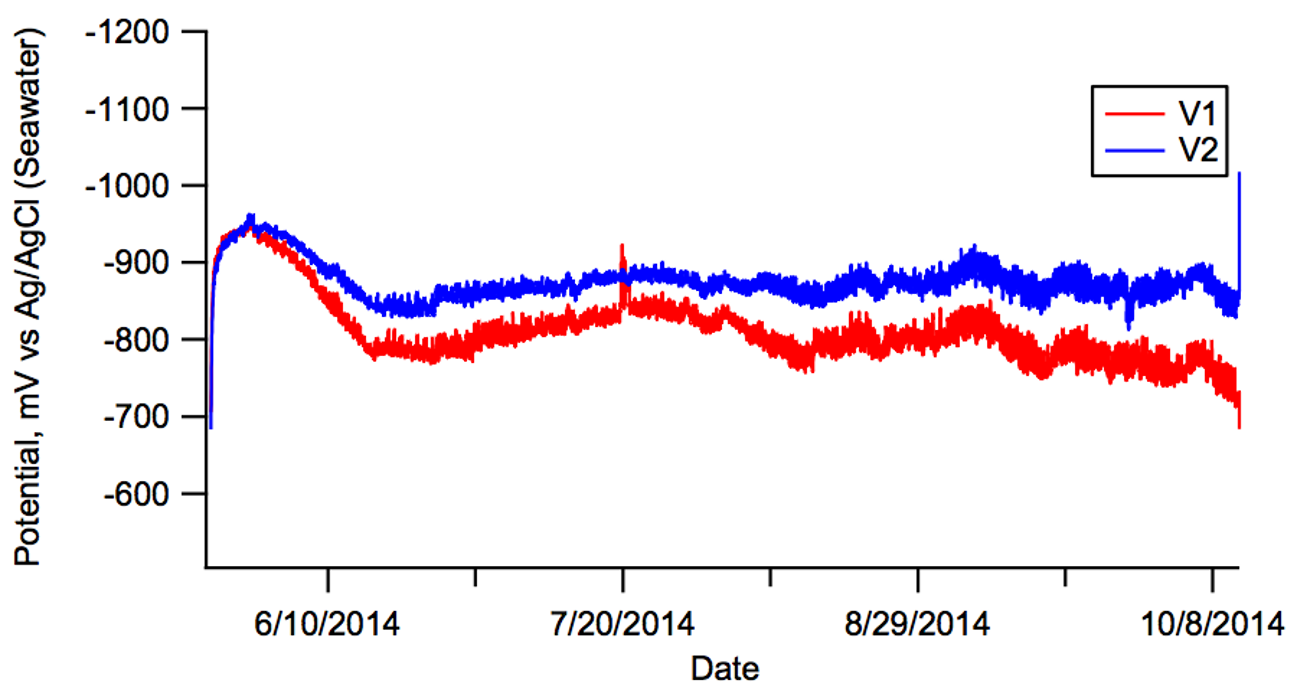

Figure 1 below: Recap CP potentials as a function of immersion time. Note: The reference electrode was activated zinc (-1056 mV vs Ag/AgCl in Seawater). There is a 170 mV internal shift between V1 and V2 due to the hardware that has been removed.

Results

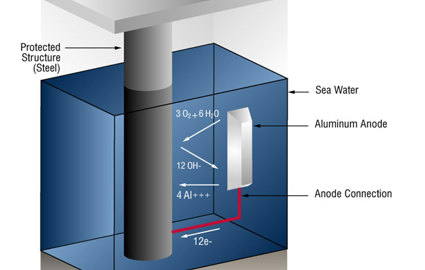

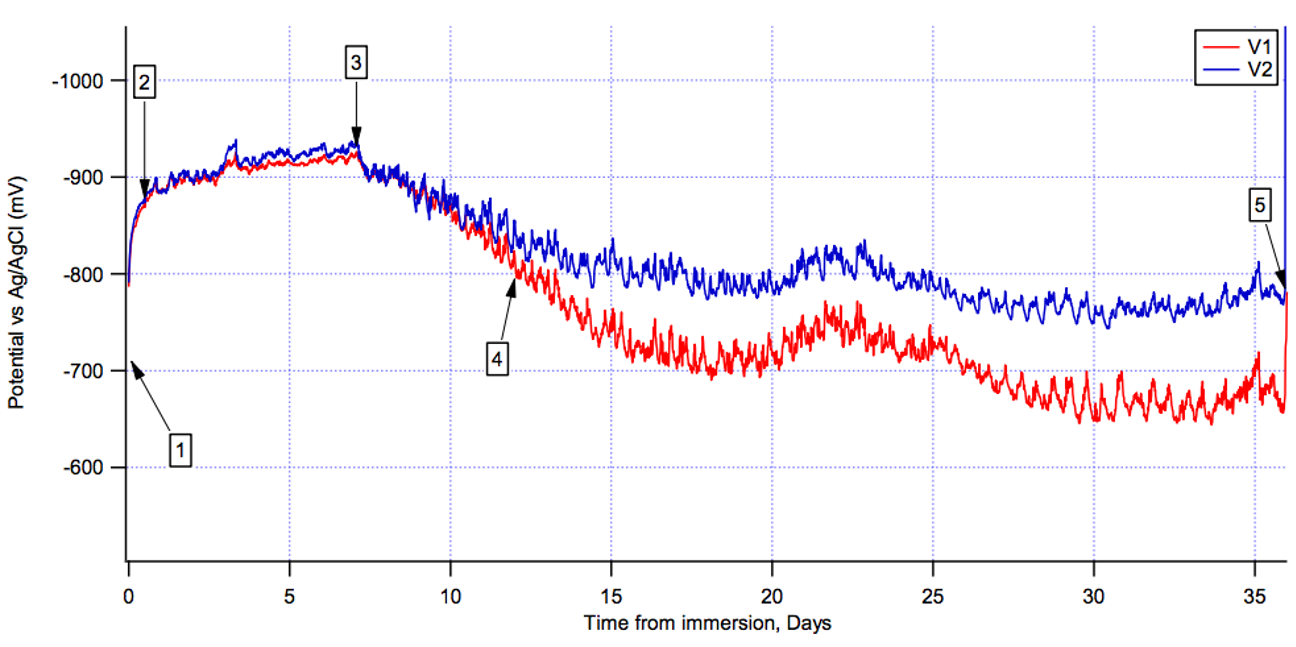

Based on the results of the first deployment, more anodes were added to the stack. The Recap™ remained in the same location and the stack returned to service. When the logged results from the second deployment were analyzed, a marked improvement in CP performance was noted by the addition of anodes. Potentials had shifted to marginally acceptable levels. Further recommendations were made to:

1. Touch up painting,

2. Thoroughly wash down the stack with fresh water after each deployment

3. Replace spent anodes on a regular basis, even those tough to access

4. Test continuity regularly

Result

After the additional recommendations were implemented, the operator continued to observe good CP performance on subsequent deployments. The two sensor locations are still electrically isolated from one another, and the results can be seen below.