Technical Paper

Corrosion control methods for deep water floating production equipment

by James N. Britton and Richard E. Baxter (2003)

Abstract

The rapid growth in the deep-water production sector worldwide has spawned a whole new generation of floating production equipment. This paper will deal with some of the unique corrosion challenges presented by these production systems, and how corrosion is being managed using innovative coatings, new cathodic protection designs and corrosion resistant materials. The paper will also address some unique monitoring and inspection issues that arise for these structures.

Introduction

The new generation of floating offshore production systems such as Floating Production, Storage and Offloading facilities (FPSO), SPAR (originally designated a Single Point Articulated Riser, now generically applied to cylindrical floating structures), Tensioned Leg Platforms (TLP), and Deep Draft Caisson Vessels (DDCV) present a number of unusual corrosion control challenges. This can be attributed mainly to the hybrid nature of these structures: similar to both conventional production platforms in some respects and ocean-going ships in others. Challenges for corrosion control arise from:

1. The use of high-strength materials on these structures.

2. The need to control weight and reduce corrosion allowance.

3. Many confined spaces and tanks.

4. A lack of operational history.

5. A high number of dynamic components and non-welded connections.

6. Inspection and monitoring can be quite difficult.

Corrosion engineers should therefore err on the side of caution when specifying corrosion control systems for these types of structures, and they often must use laboratory simulation and parallel operational history from other areas of the industry to guide them. The operator must also be aware of regulated in-service inspection requirements and allow appropriate monitoring and inspection aids to be specified during construction. Close cooperation between structural engineers (naval architects), subsea engineers and corrosion / materials engineers is absolutely critical. Recent design experience, highlighting solutions and some conflicts of opinion will be presented.

SPAR / DDCV structures

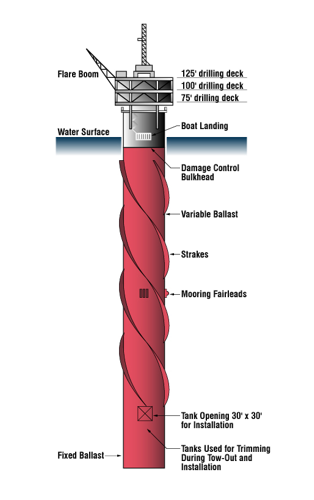

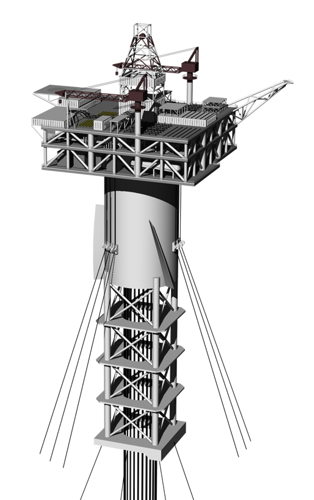

The Deep Draft Caisson Vessel (shown in Fig. 1) [5] and SPAR type structures have presented deep water operators with a cost-effective production facility for prospects with a moderate number of subsea wells and are being widely used in the Gulf of Mexico. A typical Truss SPAR design is shown in Fig. 2 [5]. These structures present the following main components, each of which has unique problems. These structures contain the majority of the problems encountered on other types of floating production systems, so an in-depth analysis of a corrosion control approach should serve well for many other floating production cases.

Figure 1 - Conventional Spar - Deep Draft Caisson Vessel,

Figure 2 - Truss SPAR Structure

Hull components

Main hull - The hull is typically a large cylindrical steel tube with a variety of internal compartments that provide buoyancy to support the topside drilling and production equipment with a central annulus (center well) through which all production is accomplished. Hulls are typically 90-120 ft. (30-40 m) diameter with a center well diameter of 30-50 ft. (10-16 m). Overall length of the hull section can be 600 ft. (183 m) or more in length. This construction presents two distinct sea-water immersed corrosion exposures.

Outer hull - Normally basic grades of carbon steel exposed to natural sea-water, these areas are typically addressed using conventional marine epoxy coatings through the splash zone and topsides and conventional sacrificial anode cathodic protection to bare steel in the immersed region. Design criteria are the same as for conventional platforms. Monitoring of cathodic protection (CP) system performance is simply accomplished using surface deployed or remotely operated vehicle (ROV) interfaced monitoring equipment. Be aware that some areas of the hull that are the outer wall of internal tanks may require some type of wall thickness monitoring. This can be accomplished with an ROV; however, the inspection locations should be clearly marked and treated to prevent excessive marine growth accumulation.

Center well - Similar basic carbon steel but exposed to quiescent sea-water. Exclusion of normal sunlight reduces marine growth accumulation and densely packed riser systems make post installation access difficult to impossible, and can cause temperatures to rise a little above ambient sea-water. The net result is a slightly lower current requirement for cathodic protection of the steel on the wall of the center well. Data from early fixed monitoring systems indicates a current density requirement of 6-9 m Al sq. ft. (60-90 m Al sq. m) initially and 1-3 m Al sq. ft. (10-30 m Al sq. m) finally. A good design number for weight calculation would be 3 m Al sq. ft. (30 m Al sq. m). Again, coatings are typically used only in splash zone and emerged areas and sacrificial anodes must be flush-mounted to avoid obstructions during riser installation, a fact that must be taken into account when computing anode resistance. Be aware that additional anode weight must be provided to offset current losses to the riser systems (which will be discussed further).

There are also a series of guide-frame structures within the center well; these guides restrict lateral movement of the riser systems during vessel relocation about its operational footprint and offset normal hydrodynamic forces. It is important to locate anodes on these guide frames, as they could be shielded from anodes on the inside wall. Bear in mind that it is these anodes that will provide a large proportion of current drained to the risers through fortuitous contact.

The limited post-installation access to this area makes it a good candidate for fixed reference electrodes to monitor CP system performance. Basic dual element electrodes (Figure. 3) can be conveniently hard wired to the surface.

Polatrak® DR-2 permanent reference electrode (dual element)

This enclosure contains a zinc and silver chloride permanent reference electrode.

Truss section - Most recent designs utilize a truss section attached to the base of the main hull to support the bottom main ballast tank at the base of the SPAR structure. The truss is typically 300-325 ft. (91-100 m) long. Construction is standard tubular steel members with periodic heave plates, which provide guides for the riser systems. The truss section is normally left uncoated and fitted with conventional sacrificial anodes. Design criteria and monitoring are the same as for a conventional offshore structure in equivalent water depth.

Main hull tanks - The main hull will contain a number of internal compartments. Some of these are void tanks that contain only air and are never flooded. Other tanks are variable ballast tanks which will see raw seawater some of the time and will be largely dry for the majority of the life. Being a part of the hull, these compartments are fabricated from basic grades of carbon steeL It is not uncommon for these tanks, particularly the variable ballast tanks, to be heavily baffled and reinforced thus creating a large number of shielded compartments.

Void tanks - These tanks are usually vented to atmosphere and thus cannot be fully deoxygenated. They are often susceptible to condensation on the inner walls. Access is possible through man-ways, and periodic visual and non-destructive examination is always a part of the required in-service inspection program. Access to effect coating repairs during operation is possible but economically undesirable. Two basic approaches may be adopted; economics will usually determine the most desirable approach.

1. Coating as the main control possibly supplemented by vapor phase control as a backup method. Where allowed, coal tar epoxies fill the role well, being reasonably surface preparation tolerant. Other two-or-three-coat marine epoxy systems will provide equivalent protection. Vapor phase inhibitors should contain soluble inhibitors to inhibit any condensed water and control corrosion at coating defects.

Remember that these tanks will require some non-destructive testing, often to gauge hull thickness on outer walls or to perform weld inspection on critical joints (particularly deck connections) that are only accessible from inside the tank. While advanced NDT techniques such as ACFM, Pulsed Eddy Current and some advanced Ultrasonic methods allow evaluation through in-situ coating, it may be worth leaving some controlled bare spots as back-up test locations.

2. Dehumidification can be a very effective method of void space corrosion control. It is simplicity itself; no water = no corrosion. Vapor phase control as a secondary method is a smart strategy should the dehumidification system not be 100% for any reason. This method offers the lowest cost in many cases; it may be necessary to include serial weight loss coupon arrays at strategic in-tank locations as a method to verify level of corrosion control attained over the life cycle. Coupon systems should be retrievable without tank entry. This allows regular retrievals between entry inspections to closely monitor corrosion rates.

Variable ballast tanks (hard tanks) - Coatings and sacrificial anode cathodic protection are required in most cases. It is important to locate anodes in all compartments and distribute them preferentially lower in the tank to be commensurate with expected life cycle surface wetting times. Maintenance current densities for bare steel in these environments should be 3 mA/sq. ft. (30 mA/sq M).

Particular attention should be paid to the coating quality in the upper areas of the tank likely to be in wet atmospheric service for much of the time. In these areas, it is worthwhile considering the use of metallic based primers or even thermally sprayed aluminum (TSA) as a stand-alone coating or as an epoxy primer.

In-service access to these tanks is extremely difficult if not impossible; it is therefore wise to include permanent reference electrodes on the lower surfaces of these tanks with signal cables to the topsides.

Permanent ballast tanks - On the design in question, there is a single large tank structure at the base of the floating unit. This is called the "soft tank" or permanent ballast tank. Again, construction is basic grades of carbon steel. The external surfaces of these tanks may be simply left bare and be cathodically protected. The inside surfaces present a fairly unique problem.

In order to provide maximum negative buoyancy at this location on the structure, it is necessary to fill the tank not only with sea-water but also with additional dense material. The ballast of choice is magnetite (Fe3O4) in a granular form. There is mixed opinion on the long-term effects of this strategy and little or no historical data from a field installation. Some FAQs are:

1. Is there a risk of galvanic action between the magnetite and the steel?

2. Will the magnetite drain cathodic protection current meant for the underlying steel? Or will it shield the steel?

3. What will happen to sacrificial anodes if located under the magnetite? Are zinc anodes a better option than aluminum (certainly if increased weight is desirable)?

4. Is there any risk of microbial influenced corrosion (MIC) in these tanks under the magnetite, particularly the anaerobes?

Based on the little that we do know [1] the most likely answers are (respectively):

1. No.

2. Current drain does not appear to be a risk. The question of shielding is unproven in a field situation, but is considered unlikely.

3. No long-term data are available; in the short term it has been observed that black-colored corrosion products appear on the anode surface, but the long-term effects of the anodes corrosion product on its performance are unknown. There is no long-term information to suggest that zinc or aluminum will have any specific advantage over the other.

4. Research is required on this subject.

Bearing the above in mind, conservatism is strongly recommended. Using anodes both above and below the magnetite a maintenance current density of 3-4 m Al sq. ft. (30-40 m Al sq. m) is recommended; coat the tank particularly where the magnetite contacts the steel. Use a one-shot biocide. Install reference electrodes as well as current density and anode current monitors both above and below the magnetite surface. When the full long-term effects are known, it may be prudent to recommend a less-stringent strategy.

Production riser components

The riser systems on this type of structures are referred to as top-tensioned risers (TIRs). They are actually small structures within a structure, having their own buoyancy systems to support them. The only designed contact to the hull structure is through the topside flow-line connections which are above water. Having said this, there is a very high probability of fortuitous contact through mechanical interference with the hull. The riser systems are free to move completely independently of the hull. The extreme mechanical loading and complexity of these systems provide a whole new set of concerns regarding corrosion control. The main areas of interest are:

Air buoyancy cans - These are large tank-like structures built around the outer surface of the riser conductor near the top of the riser. Thus, they are always housed within the center well of the main hull structure. There are a number of proprietary designs that are used but they have some common corrosion areas irrespective of specific design.

Outer can surfaces - These see the same environment as the center well areas of the hull. However, buoyancy is critical so weight loading must be minimized. Anodes are not a good choice for this reason and reasons of mechanical interference with the risers’ guide frames. The stroke length on these risers can be as much as 40 ft. (12 m) or more. While mechanical interference is absorbed on wear strips on the outside of the can, there is good possibility of coating damage during installation of the risers.

Thermal Sprayed Aluminum (TSA) provides a good solution in this area. Normally, non-activated aluminum grades are used and thinned epoxy sealers are applied to the coating; 10 mils (0.254 mm) is adequate for most design life requirements. While serving primarily as a barrier, coating the TSA can also provide an adequate level of cathodic protection to small areas of exposed steel. It has the added advantage of high adhesion and low cohesion that allows it to smear if mechanically impacted, thus reducing exposed steel area. Be aware that the coating is conductive and will generally be at a potential that is 50 mV or more positive than the anodes in the hull center well, and will thus drain a small amount of cathodic protection from those anodes when contact between the structures exists. A design rule of thumb is to consider the TSA as a 90% efficient coating; another reference [2] says I m N sq. ft. (10 m N sq. m). These numbers equate to about the same amount of CP.

Inner can surfaces - Here there is more variation in environment and recommended corrosion control based upon the air can design. In normal operation the cans are mainly void. They may, however, have an open bottom that is seawater exposed. Depending on the rate at which oxygen can be consumed and replenished, it may be prudent to coat the inside surfaces and provide a limited number of anodes at the base of the cans. Epoxy coatings are favored due largely to the difficulty of applying TSA to the inner surfaces. Depending on the can fabrication method, there may be some internal areas that are subject to damage from outside closing welds, so take this into consideration. Normally, the cans are filled with nitrogen in order to exclude the sea-water during installation and periodic re-filling is recommended to keep oxygen concentration to a minimum.

Main riser sections - The main riser sections are of pipe-in-pipe type construction with the outer pipe acting as a conductor. At the base of the riser that may be several thousand feet long there is a stress joint. (There may also be a similar section near the point of exit at the base of the hull - referred to as the keel). For "dry tree" systems there will be a tieback connector that connects the riser to the marine wellhead. Riser sections are installed in the field and are mechanically coupled. The annulus between the riser and the outer pipe is usually flooded with seawater. Mechanical spacer I centralizers are clamped to the inner riser pipe to control movement within the conductor pipe. In addition, there may be external vortex-shedding strake sections clamped to some areas of the risers and syntactic foam buoyancy modules clamped around others.

Outer surface of conductors - These areas are exposed to seawater (except inside the air cans) and see all resistivity layers in the sea-water as they transit almost the entire water column. The use of conventional coatings with bracelet anodes has several drawbacks:

1. Possible shielding and coating damage under clamped strakes and buoyancy modules.

2. Possible resistive buildup through mechanical joints.

3. High risk of mechanical damage during installation coupled with the need to minimize outside diameter upsets that may snag during running operations.

4. Weight limitations.

For these reasons most systems use sealed TSA as the corrosion control. The advantages as previously stated also address the drawbacks listed above. An additional incentive is the competitive cost of applying TSA to standard tubular sections in large volume. Consider the following points when formulating an overall strategy:

• Don't forget to coat the riser couplers; they will receive some damage from makeup tooling. Bare or poorly coated couplers could drain the TSA unduly, particularly in the mid-water sections of the riser.

• If the riser has designed or fortuitous electromechanical contact with other structures at its extremities, ensure that adequate additional anode weight is provided to account for current drain to the riser. Attenuation models can be used to predict the length of influence from each end and should be used when calculating amount and location of additional anode weight.

• It is also critical to ensure that the riser with TSA is not coupled to a large under-protected steel entity, as this could irreparably damage the TSA coating and compromise the protection system.

Internal surfaces - The outside of the actual riser pipe should be treated like the outside of the conductor (TSA coated). The inner wall of the conductor can be left bare if seawater in the annulus is suitably inhibited. Centralizers are always non-metallic to prevent wear but also to ensure no metallic contact exists between inner and outer pipes. Take care when specifying fasteners for the centralizers, as these will be electrically isolated from everything but could be subject to crevice corrosion if improperly specified. A precise knowledge of the annular fluid chemistry is required before specifying. However, avoid thin film non-metallic coatings on carbon steel and low-end 300 series stainless steels 316 or lower.

Stress joints - As the name suggests, these joints are designed to take the major share of bending moment on the riser. They are therefore made from high strength materials with good stress characteristics and are located in the outer conductor pipe. Some titanium grades are particularly suitable from a mechanical standpoint and are therefore a common choice in many systems. The propensity of titanium to suffer hydriding under cathodic protection at certain levels provides a dilemma, one made more difficult by the lack of long-term field data and the very high consequence of a failure. A number of articles have been published on these phenomena [3,4]. As previously stated, the high risk and limited experience should justify a conservative approach. Three basic methods are available and are often specified in combination, as each is designed to control the surface potential on the titanium.

1. Isolate the titanium from the rest of the system. This can be accomplished using flange isolation materials or a specially-constructed isolation joint at each end of the stress section.

2. Cover the titanium to stop cathodic protection. Heavy elastomeric coatings have been used, as they provide a tough yet flexible barrier. However, this can be difficult to apply and other coatings may be suitable. Be sure to cover all the titanium; flanges can de difficult. If this is the only method used, it is wise to develop a proven field repair procedure and an in-situ repair procedure in the event that the coating barrier is penetrated.

3. Ennoblement systems couple controlled areas of a noble material to the titanium to depress its potential. This method is the least desirable of the three since it will impose a drain on the CP systems and the term polarization data are very limited, to say the least.

Whichever method is used, these areas should be subject to close investigation during in-service sub-sea inspections. Potential measurements on non-essential titanium coupons tied to the stress joint that can be stabbed by an ROV interfaced CP probe can provide good operational verification that the stress joint is isolated.

Tie-Back connectors - The tie-back connector may or may not be electrically isolated from the riser above. In either case, it can be treated as an extension of the riser and receive the same corrosion treatments. Ensure that if TSA is used that the wellhead to which it's connected has adequate and compatible levels of cathodic protection.

Wellhead components

In deep water it is common practice to pre-drill a number of wells and then temporarily cap them until the production structure can be located onsite. Some of these pre-drilled wells have nowhere to attach anodes for corrosion protection. In these cases it is prudent to install a pod of anode material (Figure. 4) which can be electrically tied back to one or more of these wells using ROV-installed clamps (Figure. 5). These pods can produce currents in the tens of Amperes range. Pod installation is straightforward, and an added benefit is that the current from the pods can be easily monitored using an ROV stab interface.

Figure 4 - RetroPod™

Seabed anode pod tied to jacket with a tieback clamp. Current-monitoring stabs with cathodic protection probe are taken at the the top of the steel part of the Pod.

Mooring components

Lateral mooring systems are required to enable the hull structure to be moved around its operational footprint. These multi-leg systems comprise several key components that need to be addressed. Obviously the moorings are subject to very high loading and a corrosion failure could be very costly.

Upper level components - At the surface the moorings comprise a long section of chain, guided by a fairlead structure attached to the hull.

Fairleads - These are basically a large sheave on a hinged support through which the mooring chain makes the turn toward the seabed. They are normally located near the bottom end of the main hull structure. Cathodic protection is a suitable method for corrosion control, but the following precautions are required:

1. Ensure that a flexible continuity jumper cable is provided between the fairlead structure and the hull.

2. Ensure that current losses to the chain are calculated when sizing anodes.

Upper chains - Chains are very difficult to protect from corrosion due to their construction and operational requirements. This is one area where a generous corrosion allowance is normally provided. The problem is that they will draw cathodic protection (CP) current from structures to which they are electrically connected; the degree of connectivity is difficult to predict or quantify. A rule of thumb is to assume that approximately 200 ft. (60 m) of chain is likely to pick up CP in each direction away from a probable contact point. It would be difficult to locate sufficient anode material on the cheek plates of the fairlead to satisfy this drain, hence the importance of ensuring electrical continuity between the fairlead and the hull.

Catenary mooring lines - This is the long section of the mooring through the water column to the seabed and is usually a large-diameter spiral-strand wire rope for most of its length. Large connectors are used to couple the rope to the upper chain section and the lower chain section.

Wire ropes - There are a number of commercially-available rope designs that adequately address corrosion control. Usually, rope strands are coated with either zinc or a zinc / aluminum alloy, the bundle is often treated with a blocking compound to restrict the water path to the inner strands and the whole bundle is sheathed with a polyethylene jacket. This scheme has proven to be quite acceptable in most cases.

Connectors - The connectors are normally provided with anodes directly attached to the body. Some designs provide electrical isolation of the connector. This is favorable, particularly when connected to a chain, and again, it is difficult to provide enough anode material to cover losses along the chain. The bearing surfaces of these connectors are usually sheathed or lined with a hard corrosion-resistant alloy which is cathodic to the connector body material, so it is important to maintain protected potentials on these areas.

Seabed components - The lower sections of the moorings usually comprise of a "ground chain" section, which is connected by shackle to either an anchor or an anchor pile. While corrosion rates are low in this region, some operators require protection. Given the difficulty of attaching sufficient anodes to the pile or anchor, the anode pod concept previously described can be a viable alternative.

Export riser components

Export risers and flow lines from remote wells are either steel catenary design or may utilize flexible sections. Various methods have been used successfully utilizing either conventional Fusion Bond Epoxy (FBE) type coatings or TSA. Anodes can be located on the riser catenary section but some operators prefer to use anodes located at the touch-down area and on the hull to provide protection from the ends.

Summary and conclusions

When formulating corrosion-control strategies for these systems, the following points are important:

1. Ensure system compatibility between all components and make sure there is an overview material compatibility review performed.

2. Consider in-service inspection requirements when designing systems.

3. Remember to account for CP losses to TSA coated components and other unprotected entities.

4. Use conservative designs throughout.

References

[1] In-House Deepwater Corrosion Services Study - Unpublished.

[2] DNV RP B 401 (1993) Section 6.3.16

[3] Jeih Ing & Paul Chung "A Study of Hydriding of Titanium in Sea-water Under Cathodic Polarization" CORROSION 86, Paper #259

[4] Ronald W. Schultz "Guidelines for Successful Integration of Titanium Alloy Components into Subsea Production Systems" CORROSION 2001, Paper# 003

[5] Operating Company Web Sites

Want to receive an email when Deepwater publishes new corrosion-related technical papers, case studies, and more? Sign up for our Corrosion Newsletter using the form below. You can unsubscribe at any time.