Technical Paper

Cathodic protection monitoring of offshore pipelines and structures in Alaskan waters

by John P. LaFontaine and Jim Britton (2000)

Abstract

Pipelines and structures located offshore of Alaska face unique challenges to monitoring cathodic protection. Advances in cathodic protection monitoring technology are discussed. New portable ROV instrumentation as well as fixed monitoring of parameters affecting cathodic protection system performance are reviewed. Case histories from the southern coast of Alaska as well as Arctic waters are detailed.

Introduction

It is common knowledge that cathodic protection (CP) is necessary to limit corrosion on metallic structures in marine environments. Monitoring cathodic protection can provide valuable data to owners and operators regarding:

1. The level of protection.

2. The remaining service life of the system.

3. Improvements for future designs.

In the environmentally sensitive coastal waters of Alaska, it is critical that the performance of the CP (cathodic protection) system on a structure or pipeline can be monitored. From the fast currents of Cook Inlet to the Frozen Beafort Sea the marine environment of Alaska presents many unique challenges from a cathodic protection standpoint. The current density required to achieve polarization on steel in Cook Inlet is over 6.5 times higher than that required in the Gulf of Mexico. In addition the cold temperatures of these waters are as much as 30% less conductive that ambient waters. The nearly year-round ice cover and permafrost make the Arctic one of the most challenging environments yet encountered by corrosion engineers.

CP Monitoring - General

The basic criteria for cathodic protection of steel in sea-water is that it is polarized to at least (-) 0.800 Volts vs. Ag/AgCl (silver / silver chloride) or (-) 0.850 Volts vs. Cu/CuSO4 (copper / copper sulfate). This value can be determined by employing either reference cell, but typically in sea-water silver / silver chloride is used. Measuring the potential will tell you if are currently protected. However measurement of other parameters is necessary to determine the remaining service life of your system. Among these are the current density pick-up on the steel and the anode current output. These values can be compared to design values to determine if the system is operating as expected. On coated structures i.e. pipelines, anode current output can be used to determine the efficiency of the coating.

Cook Inlet

Several factors make Cook Inlet one of the most corrosive marine environments for steel structures in the world:

1. Extreme tidal ranges create tidal currents as high as 8.7 knots (1). The high velocity water provides constant oxygen replenishment to the steel surface. In addition sand and other particulates are churned into the water column, in effect "blasting" the steel surface, preventing it from forming carbonate layers, which would otherwise decrease current demand.

2. The water temperatures are cold, ranging from 50 °F (10 °C) to 29 °F (-2 °C). The cold water has a high dissolved O2 concentration, which further increases current density demand on the steel (1).

3. The resistivity of Cook Inlet water is as much as twice that of ambient 77 °F (25 °C) sea-water. This effect is a result of the low temperature as well as fresh water input.

It is imperative in such conditions that a comprehensive cathodic protection monitoring program is followed.

Pipeline surveys in the Cook Inlet - There are a number of critical aging pipelines in the Cook inlet that have only ever been surveyed using trailing wire type remote electrode techniques and some riser drop cell readings. It is now well accepted that these surveys give no detailed information regarding the true pipe potential unless the electrode position with relation to the pipeline is well known, and the system is corrected for the IR errors caused by the impressed current system. Many of the pipelines are installed using pull tubes so that even the drop cell readings are meaningless.

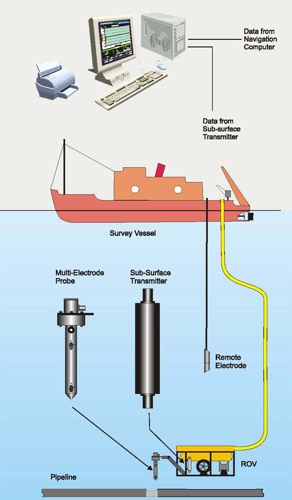

Two or three electrode techniques would provide better data validity providing that periodic pipeline contacts can be made to re-calibrate the true remote pipeline potential (Figure 1). This can be difficult because most of the pipelines are concrete weight coated for stability and mechanical protection, so if the pipe doesn't have anodes (bracelets), there is no way to calibrate unless concrete is removed.

Figure 1 - Offshore pipeline cathodic protection survey method. (courtesy of SubSpection Ltd.)

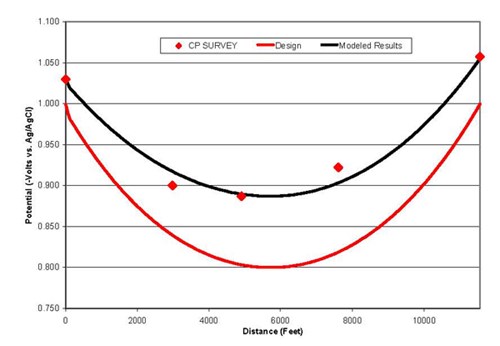

Potential attenuation modeling - Understanding and recent improvement in techniques has made modeling much more accurate, and if a few parameters can be measured on the line, predictive models can be used to estimate the worst case scenario of potential versus coating efficiency. Fixed or retrofitted permanent monitors can provide these reference points. This approach is particularly effective on pipelines that use impressed current. An example of a recent survey illustrates this approach (Figure 2). A predictive potential profile was determined before the pipeline was installed for the purposes of designing the CP system. After installation and start up, the pipeline potential was measured at 5 locations. The original model was recalculated using the field measured endpoint potentials. The close agreement between the field measurements and the model confirm the validity of this approach.

Figure 2 - Modeled potential profiles compared to actual field data on a marine pipeline.

Production facilities - Economic and logistic drivers make fixed instrumentation preferable to surveys with portable instrumentation. The same extreme marine conditions that make cathodic protection a challenge in Cook Inlet also make diver and ROV work very difficult. This is particularly true on jackets. Impressed current CP (ICCP) systems or ICCP/galvanic anode hybrid systems are required to achieve the high current demands in Cook Inlet. Fixed reference electrodes distributed across the structure are critical to evaluating system performance. Such an approach was used on the Marathon Steelhead platform. This four-pile structure was set in 183-ft. (55.5 M) of sea-water. An array of Ag/AgCl and Zinc reference electrodes were installed down both sides of one leg at 20-ft. intervals. By monitoring the steel potential with such an array, the current output from the ICCP system can be optimized. On Steelhead, the initial current output was 2100 A. After 30 days however it was determined that to achieve the proper potentials, output could be lowered to 960 A. After two years of service output was lowered to 628 A. The monitoring system allowed frequent potential measurements to be made simultaneously at many locations.

The Arctic Ocean

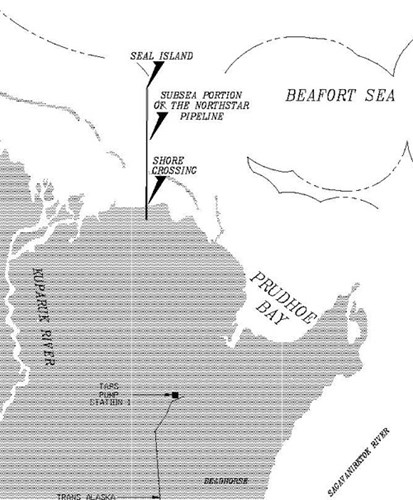

A project to develop the Northstar oil field, located in the Beafort Sea, marked the first time in the Alaskan Arctic that a warm oil production pipeline, buried in the sea floor, has been used to transport oil and gas from a manmade offshore island (Figure 3). Fixed cathodic protection monitoring on this pipeline is a necessity due to environmental concerns and logistics.

Figure 3 - General layout of the subsea portion of the Northstar pipeline.

The overall strategy was to measure the effectiveness of the cathodic protection system with a combination of fixed monitors supplemented by a survey program. A sacrificial anode system was used on this line instead of impressed current ground beds due to the high resistance of the permafrost. Near the shore crossing (Point Storkersen), the following instruments were installed:

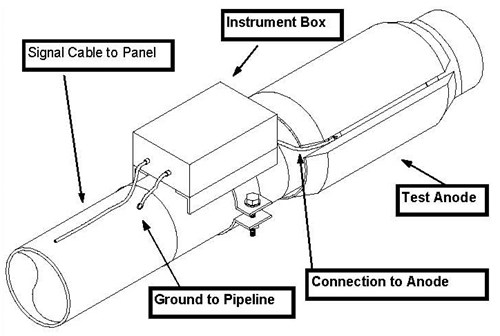

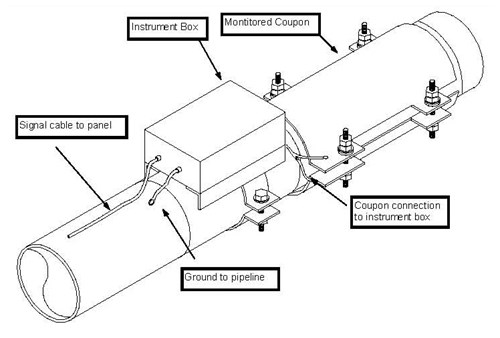

1. Anode monitor (Figure 4)

2. Current density monitors (Figure 5)

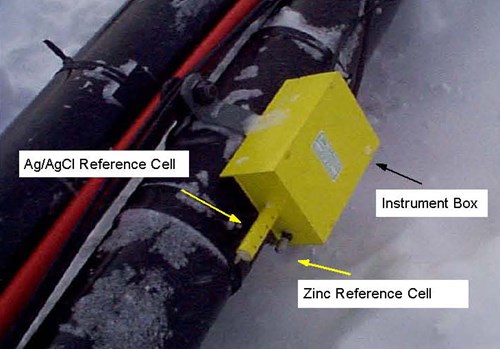

3. Permanent reference cell (Figure 6)

4. Monitoring panel (Figure 7)

Figure 4 - Schematic of monitored anode

Figure 5 - ROV interrogating a test panel

Figure 6 - Permanent reference cell

Figure 7 - Monitoring panel at the shore crossing

Each one of these monitors had Ag/AgCl (silver/silver chloride) reference cell, a zinc reference cell, and a temperature transducer. Initial readings from the system after installation indicates the cathodic protection system to be working optimally. The current output from the test anode was below 0.00001 amps. The pipeline potential was measured at (-) 1.068 V vs. Ag/AgCl. The very low anode current output combined with the near anode potential of the pipe indicates that the CP system is working very well. The effectiveness of the coating system was confirmed as data from the coated CD monitor indicates approx 100% coating efficiency. The measured sea-mud temperatures of 26 to 28 °F (-3.3 to -2.2 °C) were in agreement with geographical survey data.

Future developments

It is probable that the development of new thermally applied metallic coatings will be a part of future deepwater or high temperature CP systems. Large capacity mid-depth systems will certainly shift more toward impressed current, as cost and flexibility become more important factors. The future success of these systems will depend largely on information gathered from monitoring systems installed on the early deployments of the technology.

References

1. C.E. Hedborg, "Cathodic Protection in Cook Inlet Arctic Waters", Materials Performance, February 1991.

Want to receive an email when Deepwater publishes new corrosion-related technical papers, case studies, and more? Sign up for our Corrosion Newsletter using the form below. You can unsubscribe at any time.