Technical Paper

Cost saving offshore cathodic protection retrofit methods

by Jim Britton (2002)

Abstract

Many offshore structures (largely platforms and pipelines) will require a cathodic protection retrofit at some point during their lifetime. This is due to the age limitations of the original cathodic protection anodes and operators' new desire to extend the life of existing offshore infrastructure. This paper explores the conventional methods of anode replacement and then compares them to the newer methods developed by Deepwater Corrosion Services and others. These new proprietary products and methodologies are designed to cut installation time, while still providing an excellent life extension for the asset of up to 25 years.

Introduction

Many offshore structures and pipelines are reaching the end of the designed life of their original cathodic protection anode systems. The requirements of each life extension project will vary from adding one or two years through to adding over 20 years to the original design life of the equipment. The historical approach to cathodic protection retrofit has been to replace anodes on a one-for-one basis, using divers or ROV's to assist a crane in lowering clamp-on aluminum anodes down to the members. This approach is extremeely expensive and completely unnecessary. There is a tendency in the industry for asset owners to misinterpret the reasons why cathodic protection systems are designed differently for a retrofit than they are for new structures. While the designs can look very different, the driving force for both designs is the same: to satisfy installation requirements.

For example, a pipeline bracelet anode is designed to look the way it does to facilitate pre-installation (before pipe lay) on the pipeline; the shape of the anode is designed so that the pipe can be easily laid with the anodes in place. In truth, the bracelet anode is possibly the worst configuration that an anode could be (from the cathodic protection engineer's standpoint). The resistance is high, the utilization factor is low, the manufacturing cost is high and the "throwing power" is poor.

Another example is the conventional platform anode. Anodes are attached by welding extremely stout pipe cores to the structure. Why? To withstand launch forces and/or pile driving during installation. Again the cathodic protection design is predicated on the installation method. Is this the best way to install an anode on a large bare steel structure? Of course not; efficiency is reduced, the standoff distance is not optimized, and the cost of all those welds is significant.

When we are charged with designing an anode retrofit system, most of these constraints disappear, because the structure is already in place. As a result, when plannign a CP retrofit, a cathodic protection designer should not be limited in any way by the original design methodology.

The cost of retrofitting anodes

When analyzing the cost of a retrofit project, the driver is always the same. Cost of installation always drives the project budget. Therefore, the design should focus on reduction of installation cost without sacrificing mechanical reliability. Some of the obvious ways in which this may be accomplished are:

On pipelines

1. Minimize the number of locations on the pipeline that have to be visited

2. Select areas where the depth of cover is minimal or the pipeline is exposed on the seabed

3. Minimize bottom time requirement at each location

4. On deeper projects, use ROV’s rather than saturation divers

5. Carefully evaluate and compare costs of 4-point moored systems vs. dynamically positioned equipment

6. Evaluate Impressed Current, Sacrificial Anode and Hybrid solutions at design phase

7. Have the flexibility to adjust the retrofit plan offshore based on survey results obtained as the installation progresses

On platforms

1. Minimize the number of anode installations.

2. Minimize the amount of marine growth removal.

3. On deeper projects, use ROV’s rather than saturation divers. Use shallow diving support to accomplish high dexterity tasks such as marine growth removal, installation of splash-zone pull tubes etc.

4. Have the flexibility to adjust the retrofit plan offshore based on survey results obtained as the installation progresses.

5. Carefully plan topside rigging and set equipment prior to mobilization of the subsea installation spread.

6. Evaluate impressed current, sacrificial anode and hybrid solutions at design phase.

Designing cathodic protection retrofits

Just as new construction cathodic protection designs are made to facilitate installation of the offshore platform or pipeline, the cathodic protection design criteria are designed to polarize a structure from native state potential, provide adequate redundancy in design to allow for some system damage during installation or for unknown environmental affects. In new construction there is little incentive to “over-optimize” if it entails any added risk. When considering a retrofit there are a number of major differences that should be reflected in the design criteria selection:

1. In all cases there will be some degree of polarization remaining, even if the structure has fallen below "protective potential criteria". In many cases the structure will still be adequately protected but will have heavily depleted anodes.

2. Design life requirement may be for only a few years, in which case it may not be necessary to optimize protective potential levels.

3. We have the benefit of being able to perform a survey to accurately define the condition, and to measure the existing polarization characteristics (current density vs. potential).

4. We have the advantage of being able to monitor both anode cathode response during the retrofit to verify design predictions.

So when designing a retrofit it is rarely if ever required to provide the same current density as one would for a new structure, and if existing maintenance current density can be demonstrated to be much lower than conventional wisdom would dictate, significant savings can be realized [1].

The importance of survey

The value of a well specified survey cannot be over estimated, this is true of both platforms and pipelines but particularly so with buried or partially buried pipelines. This is only true of a high resolution type survey [2], remote or semi-remote (trailing wire) type surveys provide little or no useful information. The most important information obtained from a detailed pipeline survey, in order of value, is:

Line location - Having an accurate position on the pipeline is essential, particularly if the line is buried. The hourly rate on the offshore equipment necessary to effect a pipeline retrofit is such that it is unacceptable to waste any time trying to locate the pipeline.

Line depth of cover - Knowing where the pipeline is exposed or has only minimal cover will save significant time and money. If a retrofit site is inadvertently selected where the pipeline is buried 2 meters deep, it could take divers many hours to excavate the pipeline, and then they would be forced to work in a deep hole where visibility would be essentially zero.

Knowing CP system performance - By measuring the field gradients as well as potential, the resilience of the CP system can be estimated, as well as any areas of significant coating damage. Having an ROV fly the line there is always the chance of obtaining a visual inspection opportunity on one or more anodes, this can provide invaluable information to the cathodic protection designer.

Verification of environmental conditions - The survey will give a good indication of seabed conditions, current velocities etc., as well as giving accurate seawater and more importantly mud resistivity information.

Armed with this survey information, the designer can first select ideal sites for retrofit anode locations based on the depth of cover survey. Knowing the current density requirement and general coating condition facilitates accurate application of attenuation models to optimize spacing between retrofit sites. Knowledge of the mud resistivity allows accurate calculation of current outputs from various anode arrays.

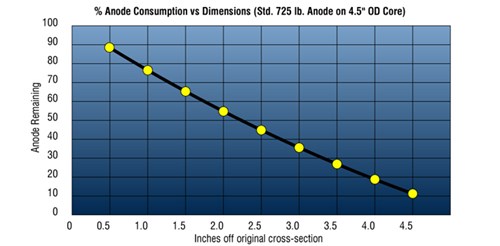

On platforms it is the same story, using an intelligent survey approach [3], [4], will yield valuable information on cathodic protection system performance. Again, structure potential data alone do not tell the whole story. Estimation of anode depletion percentage is another area where mistakes are often made. Table 1. shows a dimension vs. volumetric relationship on a typical platform anode.

Figure 1 - Relationship between anode percent consumed and cross section reduction

As can be seen, the first 12 mm of cross sectional reduction equates to 12.6% loss of metal, near the end of life the same reduction represents only 7.1% volumetric loss. Thus it is important to take accurate measurements on a few water blast-cleaned anodes to get a realistic status on remaining anode material. The benefits of an intelligent platform inspection are, in order of value:

Polarization data - Knowing the existing maintenance current density on a structure gives the designer a precise benchmark from which to work. This will always result in a lower (but still safe) current density value being applied for the retrofit. This saves time and money without adding risk.

Anode performance - Knowing the current output range of the existing anodes and their average degree of consumption allows more precise prediction of remaining life. This could result in deferring a retrofit for one or more seasons, again with no risk.

General asset condition - A typical survey will also include evaluation of the seabed condition, silt and scour and seabed debris, these are invaluable data if a seabed pod or sled approach is considered or if access to mud line framing is required. Extent and thickness of marine growth, will affect structural attachments. Verification of the type and location of original anodes may prove useful if original anodes are used to support retrofit anodes. Condition of the structure regarding existing corrosion damage, a heavily corroded structure may not be a candidate for certain kinds of retrofit.

Case histories

Bearing the aforementioned paragraphs in mind, here are three case histories of projects completed in the Gulf of Mexico in 2000. While not all of the procedures follow the ideals outlined, the application of the basic principles is apparent, as are the documented performance results and cost savings.

Case history No. 1 - 12” oil pipeline - This pipeline was installed in 1973 and runs from an offshore platform in 76 M (250 feet) of water to an onshore terminal 90 Km. (56 miles) distant. From the platform to about kilometer 24 (mile 15) the line is bottom laid, although the location of the line near the Mississippi river delta has resulted in silting over of much of the pipeline. The next 32 Km. (20 miles) or so were laid in water that was less than 125 M (200 feet) deep and was buried to a depth of 1.5 meters (5 feet). The final 34 Km. (21 miles) are laid through wetland (swamp) in pipe canal and buried a minimum of 2 meters (6 feet). The offshore section (56 Km. 35 miles) of the line was protected with zinc anode bracelets, the wetland section was originally protected with a combination of impressed current and zinc bracelets, precise records of where the bracelets started were not available. The pipeline has a 25mm (1”) thick concrete weight coat.

In 1997, the offshore section of the pipeline was surveyed using a three electrode system [2]. The survey results showed that the pipeline was still at protected potentials but that the anode bracelets were heavily depleted. The survey also showed the depth of cover on the pipeline ranged from exposed to < 3 meters (10 feet). An accurate as built plot was generated which showed the actual position of the pipeline to be as much as 30 meters (100 feet) off from the original "as built" survey.

In 2000, the pipeline owner decided to undertake a retrofit of the offshore section of the pipeline, 56 km (35 miles). The extended design life was 10 years. Review of the riser potential showed a very small decline in protected potential from the survey 3 years previous.

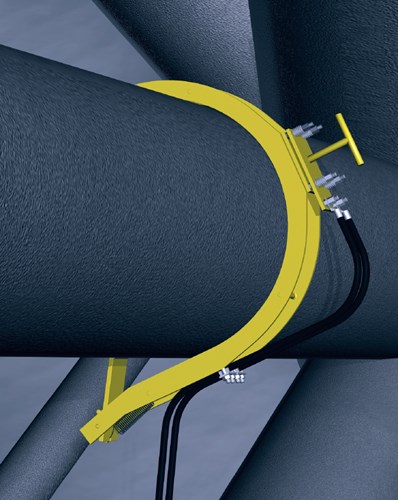

The retrofit design utilized pairs of sleds located either side of the pipeline. 3-4 meter sled-to-pipeline spacing was used. Attenuation models were used to set the maximum spacing between anode sled installations, this resulted in a value of 3650 meters (12,000 feet). Points were selected where the depth of cover was minimal or the pipe was exposed, and a total of 28 sleds at 14 sites were proposed. It was apparent that the majority of time on bottom would be taken up exposing the line and removing concrete. It was therefore decided to use a continuity clamp, designed by Deepwater, that could be installed without the need to either expose 360 degrees of the pipeline or having to remove a large area of concrete weight coating. The clamp system used (Figure 2) allowed only a small circle 100 mm (4 inch) diameter of concrete to be removed on the top of the pipeline, and required only 180 degrees of the pipeline to be exposed. It was also necessary that the clamp would pull off the line if snagged and that continuity could be assured over a wide range of temperatures without inducing a stress raising point on the pipeline. The clamp shown is a constant tension device with a hollow ground soft tip contact.

Figure 2 - RetroClamp™ Constant Tension Clamp used on concrete coated pipelines

(image has been updated from original)

Figure 3 - RetroSled™ Anode Sleds with PolaStab current measurement interface

(image has been updated from original)

Figure 4 - Polatrak® CP-Gun used to read sled current

(image has been updated from original)

Figure 5 - 8-Pile production platform – congested conductor bay

A saturation diving spread was contracted, with a shallow air capability also to handle the galvanic anode and I-tube installations. This proved to be cost effective because the deep work required was minimal and only a few diver rotations were required.

The majority of the current was to be provided by four semi-remote seabed deployed buoyant sleds deployed off either side of the jacket at a distance of 15 meters (50 feet) off the structure and the same distance from any of the pipelines associated with the structure. Each sled (Figure 8) is rated at 250 Amperes. The remainder of the current is provided by 16 x 400Kg (900 lb) dual suspended aluminum anode arrays deployed from the first two subsea elevations of the structure, immediately around the conductor bay area. The vertically hung anodes reduce effective resistance and speed installation by allowing the suspension clamp to be pre-installed then the anodes, which have “shepherds crook” style hooks to be easily engaged with simple single point rigging. Dual anodes hung from each clamp improve current distribution and optimize installation time. Flexible jumper cables ensure low resistance structural continuity.

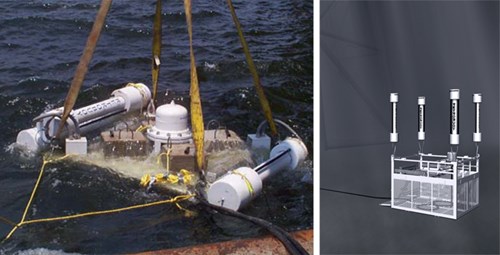

Figure 6 - 250 Ampere RetroBuoy™ buoyant anode sled deployment. Model of seabed configuration (inset picture updated)

Benefits of buoyant sled anode arrays

1. Buoyant anodes are held in seawater with no possibility to silt (which greatly reduces anode performance).

2. The individual buoys will recoil from impact from dropped objects, and every anode is individually cabled so that loss of the entire system is a low risk.

3. Dual feed cables (double steel wire armored) are used and are completely independent.

4. All cable connections are made in the central oil filled, pressure compensated junction box.

5. The system is easy to install and cost effective to build.

Other features of the impressed current system include:

1. 4 individual I-Tubes installed for the splash zone transition.

2. Individual rectifiers for each sled (250A @ 24V).

3. Wet weld quick fit cable supports routed up each leg.

4. 6 permanent reference electrodes installed to allow accurate commissioning of the system and to facilitate on-line monitoring.

Results - The results of the retrofit were excellent, in fact the current required was less than anticipated and the sleds are now operating at a little over 65% of their rated capacity. Even though the anodes were not truly remote, the effects of the impressed current system could be measured all over the platform. The installed cost comparison versus a conventional dual clamp-on anode approach is presented in Table 11. This supposes that the structure would support the weight, in truth the cost would have been much higher because anodes would have to have been removed before the new ones could be installed.

Table 9

Cost comparison of hybrid vs conventional Retrofit

| Item description | Cost |

|---|---|

| ICCP System Cost (Four Anode Sleds, Rectifiers, I-Tubes, Cables, Reference Electrodes and Cable Clamps) |

$150,000.00 |

| Galvanic Materials (16 Dual Anode Assemblies with Clamps) | $ 30,000.00 |

| Installation Cost (4 Days Subsea) plus topside Installation | $180,000.00 |

| Total Installed Cost | $360,000.00 |

|

COMPARABLE DUAL CLAMP ON ANODE SYSTEM COST

|

|

| Materials (122 Dual Assemblies @ 1080lb. Each) | $210,000.00 |

| Installation Cost (14 Days Subsea Required) | $540,000.00 |

| Total Installed Cost | $750,000.00 |

Case history No. 3 - 90M (300 feet) drilling / Production platform

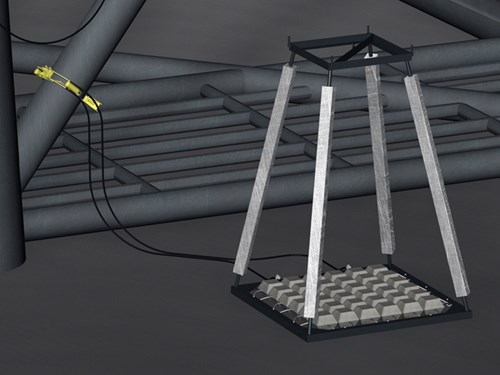

This structure was the same vintage as the previous example and was installed in the same field. The major difference is that this structure had a depleted anode system but was still polarized to average levels of (-)0.920 V vs. Ag/AgCl sw. Required design life was 15 years. An economic study showed that a galvanic system based on seabed pod arrays and shallow suspended anodes would provide the most cost effective solution. The shallow suspended arrays were the same as used on the previous example except that 24 arrays were deployed, again from the first two subsea elevations to minimize deep bottom time. The arrays were also 400 Kg (900 lb).

In addition, 18 seabed pods were deployed in 6 groups of three around the structure periphery approximately 3 meters (10 feet) off the structure. A typical anode pod is shown in Figure. 10. The pod geometry was designed to minimize mutual anode interference while maintaining a geometry and weight that was easy to handle offshore. Tie back to the structure was made through modified versions of the pipeline clamp. Each clamp accommodated 3 pods (two negative connection wires per pod) and there was facility to measure the current contribution from each pod using the same principle as the pipeline sled current monitor, only this time it was cathode based. Grab rails were also provided to facilitate ROV monitoring on future subsea inspections. Like the pipeline sleds current output was monitored from each pod to verify design calculations.

Figure 7 - RetroPod™ Anode Sled (shown in situ on bottom)

Results - Again this approach worked well and the comparative installation costs are shown Table 15. Deployment of the anode pods went very smoothly largely because of the diving support vessel which had an extending boom crane on the back deck.

Figure 8 - Installation vessel with extending crane – Ideal for offshore retrofit projects

Table 13

Cost comparison galvanic hybrid vs conventional retrofit

| Item description | Cost |

|---|---|

| Anode Pods (24) with Cables and Clamps | $100,000.00 |

| Suspended (32 Dual Anode Assemblies with Clamps) | $ 64,000.00 |

| Installation Cost (3 Days Subsea) | $120,000.00 |

| Total Installed Cost | $284,000.00 |

|

COMPARABLE DUAL CLAMP ON ANODE SYSTEM COST

|

|

| Materials (75 Dual Assemblies @ 1080lb. Each) | $130,000.00 |

| Installation Cost (7 Days Subsea Required) | $280,000.00 |

| Total Installed Cost | $410,000.00 |

Summary

Although the descriptions are brief, these three jobs demonstrate that structure specific design, good survey data and innovative application of basic technology focused on reducing installation costs can save considerable sums of money even on relatively small retrofit projects such as these.

References

[1] Mateer M W, NACE International CORROSION 91. Paper No. 233.

[2] Britton J N, NACE International CORROSION 92, Paper No. 422.

[3] Britton J N, NACE International CORROSION 98, Paper No. 729.

[4] Mateer M W, Kennelley K W, NACE International CORROSION 93, Paper No. 526.

We will send a maximum of (1) email every (4) weeks. If multiple papers are published in that period, they will be sent in the same email.

Want to receive an email when Deepwater publishes new corrosion-related technical papers, case studies, and more? Sign up for our Corrosion Newsletter using the form below. You can unsubscribe at any time.