I-Rod® lab test

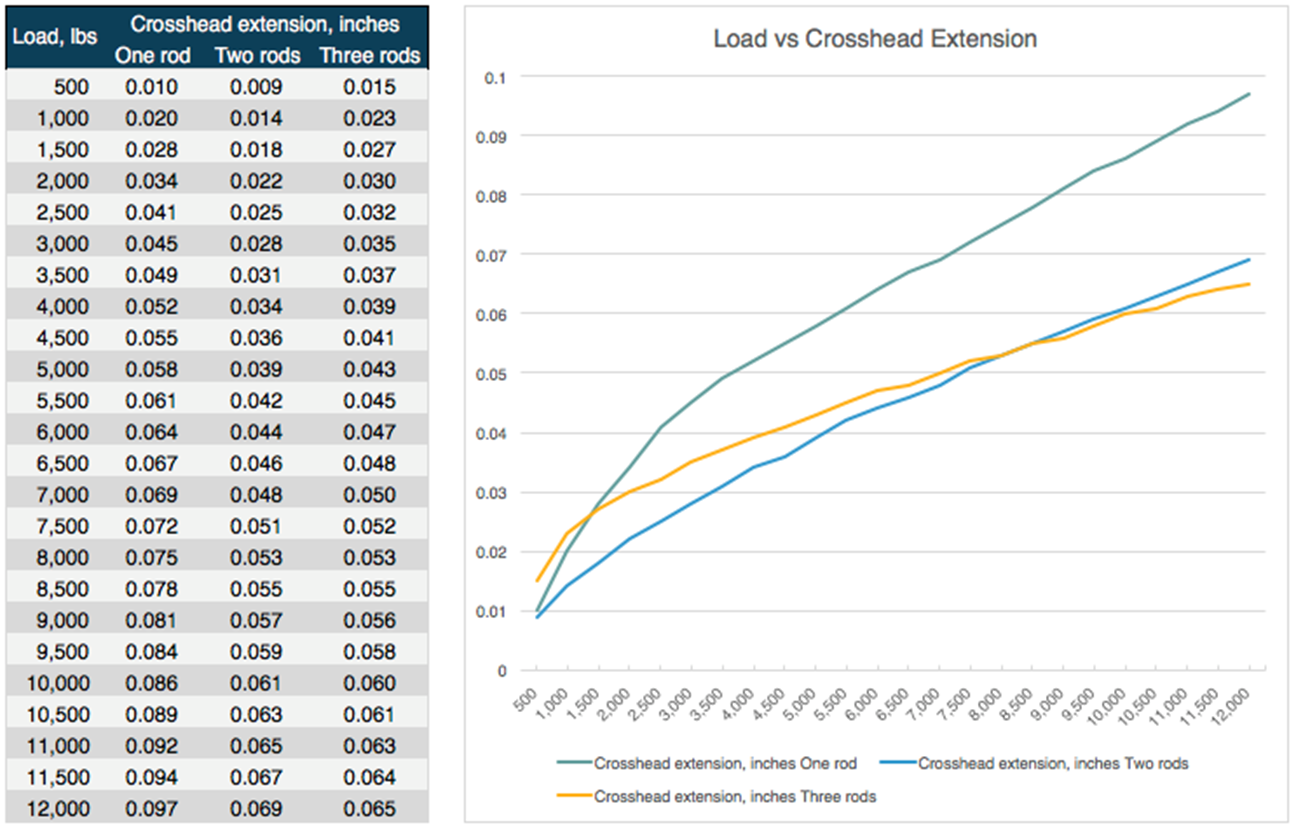

Load vs Crosshead Extension test confirms I-Rod's compressive strength

The procedure

The I-Rod® pieces were subjected to compressive loading with a fixture which simulated a 12 inch OD pipeline. Loading was applied, as shown in Figure No. 1, and crosshead extension was measured at 500 lb intervals. The I-Rods were tested in sets of one, two, and three, and a 100 lb pre-load was applied to each test array prior to any measurements. Multiple rods were tested with an 8 inch center to center width on the exterior rods.

Figure 1

How the loading was applied

Figure 2:

One bar, 6,800 lb.

Figure 3:

One bar, 12,000 lb.

| Material | Six longitudinal half-sections: 18" x 1.5" x 0.648" to 0.657" | Identification | I-Rod® Material |

| Date received | 10-21-1996 | Technician | Hugh Myers, Dennis Stanford |

| Specifications | Per client | Date of Test | 10-24-1996 |

| Test Equipment | Instron 4507, S / H H1963 | Procedure | Load vs Crosshead Extension |

The results

The load versus crosshead extension data are presented in the table below and in graphical form. The test set-up is illustrated in Figure No. 1 and various load-rod combinations are illustrated in Figures No. 2 to No. 7.